Understanding Edging Machines for ABS Materials

Edging machines tailored for ABS materials are specialized equipment crafted for the precise cutting, trimming, and profiling of Acrylonitrile Butadiene Styrene (ABS) plastic materials. These machines play a pivotal role in various industries, including manufacturing plants, construction firms, and even for DIY projects at home. The primary objective of an edging machine is to customize plastic sheets or parts by eliminating excess material along the edges to achieve clean, straight, and smooth edges.

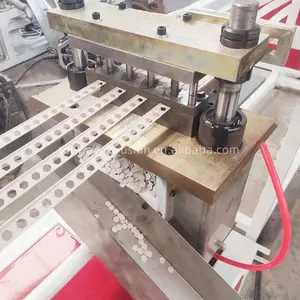

The operational principles of edging machines for ABS materials align with those of other material processing equipment. Typically, they feature a cutting mechanism that can be equipped with various blades or tools depending on the specific application. A motor usually powers the cutting action, rotating the tool at high speeds. This precision and speed enable consistent edge quality and facilitate high-volume production.

Edging machines for ABS materials are designed with diverse user needs in mind. While some are manual, with operators controlling the feed rate and material movement by hand, others are semi-automatic or fully automatic, offering a more hands-off approach and integration into production lines for enhanced efficiency. Advanced features of these machines include adjustable cutting speeds, pressure control systems, and support for different edge profiles such as straight, beveled, or rounded edges.

Varieties of Edging Machines for ABS Materials

Various types of edging machines are utilized for ABS materials, each catering to specific industry requirements. Here are some common types:

-

Handheld Edging Tools: These compact and portable tools are ideal for on-site finishing tasks like edge trimming on plastic parts or smoothing rough areas. Their user-friendly nature makes them suitable for small workshops or hobbyist projects.

-

Edge Banding Machines: These machines apply a band or strip of material to furniture pieces or cabinet doors' edges. The heat-activated adhesive on the band bonds to the board upon ironing, creating a seamless finish that blends with the surface.

-

Automatic Edge Banding Machines: Geared towards high-volume production, these machines employ conveyor systems and robots for automatic edge banding application. They are indispensable in industries like furniture manufacturing where consistent edge quality and speed are critical.

-

Multi-Function Edging Machines: These versatile machines can execute various edging tasks such as chamfering, rounding, buffing, and applying edge banding. Their flexibility makes them a practical choice for workshops requiring a range of edging processes.

Factors to Consider When Selecting an Edging Machine for ABS Materials

Choosing the appropriate edging machine for your business necessitates a thorough evaluation of several factors:

-

Material Compatibility: Ensuring the machine aligns with the specific material you work with is crucial. For instance, when primarily edging ABS materials, a machine with the right temperature range and feed speed is essential to prevent melting and achieve a pristine finish.

-

Machine Size and Capacity: Consider the size of materials you handle and the required throughput. A larger machine can manage bigger pieces and higher volumes but may demand more space and energy.

-

Edge Quality: The aesthetic of the final product is significantly impacted by the edge finish quality. Seek machines capable of producing the necessary edge type (fine trimming, edge scraping, etc.) with minimal imperfections.

-

Ease of Use: Depending on your workforce's expertise, assess how user-friendly the machine is for operation and maintenance. Some businesses prefer intuitive interfaces that necessitate minimal training.

-

Durability: Given the extensive usage, opt for machines constructed from robust materials with durable components to withstand heavy utilization.

Exploring Edging Machines for ABS Materials on Alibaba.com

Alibaba.com serves as a global marketplace offering a wide array of Edging Machines suitable for diverse industries and applications. With offerings from numerous global suppliers, this platform streamlines the procurement process by granting businesses access to a plethora of machinery options tailored to their specific needs, irrespective of geographical boundaries.

For enterprises working with ABS materials, Alibaba.com offers an efficient avenue to procure machinery meeting their operational requisites—be it for fine trimming in a manufacturing plant or precise scraping in a furniture factory. The platform's intuitive interface enables buyers to directly engage with suppliers to discuss customization options or post-purchase service needs, ensuring a tailored acquisition aligned with their business goals.

Furthermore, Alibaba.com's commitment to facilitating international trade is underscored by comprehensive services like Trade Assurance, securing transactions until successful delivery. This level of support solidifies Alibaba.com as a dependable ally for businesses seeking reliable machinery solutions to enhance their operations. Leveraging the platform's extensive network and user-friendly features, companies can effectively acquire Edging Machines contributing to their sustained success in a competitive market.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4