Understanding Acrylic Molding Equipment

Acrylic molding equipment refers to a range of machinery and tools specifically designed for the production and processing of acrylic materials. Essential for businesses involved in manufacturing acrylic-based products like signages, displays, and protective covers, this equipment ensures precise molding to maintain consistency in shape and quality, vital for commercial distribution.

The process of molding acrylic entails several steps, starting with preparing the raw material, which is then heated to a molten state within the molding machine. The molten acrylic is subsequently injected into a mold cavity mirroring the desired product. Upon cooling and solidifying, the product is extracted from the mold for further processing or finishing, typically managed by computer numerical control (CNC) systems to ensure accuracy and reproducibility.

Acrylic molding equipment operates on the principles of thermoplastic processing, leveraging the characteristics of acrylics such as clarity, high optical strength, and chemical resistance. These properties make acrylics a preferred choice in industries requiring durable and transparent materials. The machinery used in acrylic production is tailored to accommodate acrylics' specific traits like low melting points and easy flow when heated.

Varieties of Acrylic Molding Equipment

Diverse forms of acrylic molding equipment cater to various manufacturing processes and product designs. The following are some examples:

-

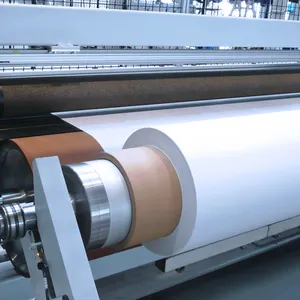

Extrusion Systems: Utilized for creating continuous shapes like pipes or rods by extruding acrylic material through a die. Common applications include crafting profiles for construction purposes or custom-shaped signs and displays.

-

Injection Molding Machines: Capable of producing intricate, three-dimensional parts with high precision and speed, often used in manufacturing medical devices, toys, and household items.

-

Vacuum Forming Equipment: Involves heating an acrylic sheet until pliable and then molding it over a form. Upon cooling, a rigid shape is formed, commonly employed in making point-of-purchase displays or protective panels.

-

Heating and Bending Equipment: Essential for shaping acrylic sheets into various forms without fracturing, typically employing heat elements to soften the material before bending, resulting in a clean and aesthetically pleasing outcome.

-

CNC Machines: Ideal for high-precision applications, CNC (Computer Numerical Control) machines cut and shape acrylics with meticulous accuracy, excelling in producing intricate parts.

Each type of acrylic molding equipment serves distinct purposes, from basic extrusion for simple shapes to advanced processes like injection molding or vacuum forming, selected based on factors such as design complexity, production volume, and the need for customization or standardization within the industry.

Selecting Acrylic Molding Equipment

The choice of acrylic molding equipment is pivotal for businesses aiming to efficiently manufacture high-quality acrylic products. When deciding on equipment for your business needs on Alibaba.com, consider the following:

-

Type of Equipment: Select the appropriate equipment type based on intended use and production volume, whether a standard injection molding machine for high-volume production or a specialized CNC machine for small-scale manufacturing.

-

Production Capacity: Assess the quantity of acrylic products you intend to manufacture, with machines designed for either small-scale or large-volume production.

-

Space Constraints: Account for available space in your facility, as larger equipment like extruders or heavy-duty molding machines may require more room compared to smaller CNC machines or laser cutters.

-

Energy Efficiency: Opt for equipment with energy-saving features to reduce long-term operational costs effectively.

-

Quality of Output: The chosen equipment directly impacts the quality of the end product, necessitating equipment capable of consistent production of the required items.

Considering these factors ensures the acquisition of suitable equipment aligning with your business's production requirements.

Acrylic Molding Equipment at Alibaba.com

For businesses seeking reliable sources of acrylic molding equipment, Alibaba.com stands out as a prime marketplace offering a plethora of machinery tailored to meet diverse manufacturing needs. With a vast network of global suppliers, Alibaba.com grants access to cutting-edge technology, enabling businesses to remain competitive in a swiftly evolving market. The platform's dedication to enhancing international trade is evident through services streamlining the procurement process, from intuitive search features to secure payment options.

Alibaba.com's user-generated content empowers buyers to evaluate suppliers' credibility and machine performance before making purchasing decisions. Furthermore, the Trade Assurance service provides payment protection until delivery confirmation, offering peace of mind. Whether scaling operations or streamlining production processes, Alibaba.com facilitates finding high-quality acrylic molding equipment tailored to specific industry requirements without compromising efficiency or security.

By leveraging Alibaba.com's global reach and industry expertise, businesses access not only a spectrum of acrylic molding machines but also a wealth of information aiding informed decisions on capital investments. Simplifying international trade through user-friendly features accommodating communication in local languages and comprehensive after-sales support services, the platform proves indispensable for small and medium-sized enterprises aspiring to expand operations worldwide.

Frequently Asked Questions about Acrylic Molding Equipment

Distinguishing Vacuum Forming Machines and Compression Molding Machines

Vacuum forming machines utilize negative pressure to shape heated plastic sheets, while compression molding machines apply pressure to pre-placed material to create a new shape, each suitable for diverse applications based on part complexity.

Choosing the Right Material Type with an Acrylic Molding Machine

Opting for the appropriate material involves considering end-use application, transparency needs, durability requirements, and exposure to chemicals or outdoor elements. Acrylic, known for clarity and weather resistance, is a popular choice.

Feasibility of High-Volume Production with Acrylic Molding Equipment

Indeed, specific types of acrylic molding equipment are tailored for high-volume production, offering precision and efficiency for mass manufacturing while ensuring consistent quality in final products.

Key Considerations for After-Sales Service with Acrylic Molding Equipment

Seek suppliers providing comprehensive after-sales services like video technical support, online assistance, and maintenance and repair services, ensuring operational and equipment maintenance support.

Customization Options for Acrylic Molding Equipment on Alibaba.com

Many suppliers on Alibaba.com offer customization options for their acrylic molding equipment, permitting requests for modifications to meet unique business requirements.

Significance of Core Components in Acrylic Molding Machines

Core components such as motors, pumps, and pressure vessels are pivotal in determining equipment durability and efficiency, necessitating adherence to industry standards suitable for the application.

Ensuring Ease of Operation with Purchased Acrylic Molding Equipment

Look for equipment featuring user-friendly interface controls, clear instructions, and intuitive design, alongside availability of technical support or training to ensure proper machine operation.

Exploring Environmentally Friendly Options with Acrylic Molding Equipment on Alibaba.com

While specific environmental claims vary by supplier, Alibaba.com listings may feature options utilizing sustainable materials or processes, promoting environmentally conscious choices.

Industries Utilizing Acrylic Molding Equipment

Acrylic molding equipment finds common application across various industries, including manufacturing plants, advertising firms, hotels, building material retailers, and printing establishments, among others.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4