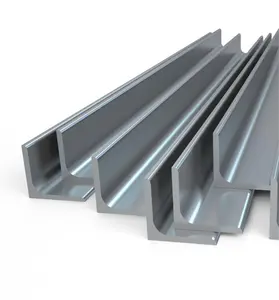

The Essence of Structural Steel Angle Lines

Structural Steel Angle Lines are pivotal in both construction and manufacturing sectors, offering essential support and reinforcement across diverse structures and applications. These lines consist of a coordinated series of machines designed to cut, punch, weld, and mold steel angles into the desired shape. A typical Structural Steel Angle Line features a band saw or shear to trim steel profiles, a hydraulic punch shear for creating holes, and an angle shear to achieve precise angle cuts. The line may be augmented with additional machinery for notching and drilling, thereby broadening its functional scope.

Entities engaged in erecting buildings and infrastructure heavily rely on Structural Steel Angle Lines. Manufacturers crafting structural elements that demand exact angles and configurations, such as mezzanine floors, trusses, or frameworks, also depend on these lines. The automation inherent in these systems markedly enhances both efficiency and precision over manual methods, thereby elevating the caliber of the end products.

Structural Steel Angle Lines function on the principles of material handling and metal fabrication. The process initiates with the loading of steel coils onto a decoiler, which then unfurls the steel. Subsequently, the steel progresses through the line's various stations, including the punching machine for hole creation, the shear for sizing, and the welding apparatus for assembly. The integration of advanced CNC technology ensures both accuracy and consistency. This mechanization not only expedites production but also diminishes labor demands and the likelihood of human error.

Varieties of Structural Steel Angle Lines

Diverse types of Structural Steel Angle Lines are available to meet specific needs and applications. Common variants encompass:

-

Standard Structural Steel Angle Line: Characterized by symmetrical dimensions on both sides, this variant is frequently employed in construction for its uniform load-bearing capacity and stability.

-

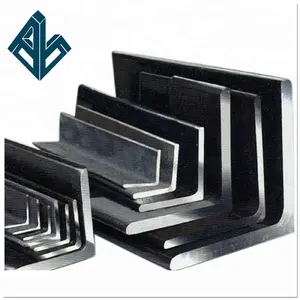

Unequal Structural Steel Angle Line: These angles feature legs of differing lengths and are selected for applications where load-bearing requirements are asymmetrical.

-

Galvanized Structural Steel Angle Line: These angles are zinc-coated to guard against corrosion, making them ideal for outdoor applications such as solar panel frames or fencing.

-

Punched Structural Steel Angle Line: Featuring pre-punched holes, these angles are lighter and more cost-effective while still providing structural integrity. They are commonly used in industrial environments or for systems like conveyors.

Each line variant is tailored to its specific use cases, informed by material attributes and design features.

Selecting a Structural Steel Angle Line

In choosing a Structural Steel Angle Line for your enterprise, several critical considerations must be taken into account:

-

Processing Services: Evaluate if your operations necessitate additional processing services such as cutting, punching, welding, or bending. Not every angle line may provide these services, so it is essential to align your selection with your processing requirements.

-

Material Quality: The steel grade (e.g., Q195-q420 series) should correspond with the durability demands of your project, as it indicates tensile strength and environmental suitability.

-

Application: The intended application of the angles, whether in building support or industrial uses, will guide the choice of the appropriate angle line.

-

Alloy Composition: For projects that require enhanced corrosion resistance or superior tensile strength, consider angles with specific alloy compositions, such as non-alloy or is-alloy.

Discovering Structural Steel Angle Lines on Alibaba.com

Alibaba.com serves as a vast international marketplace, bridging buyers with a plethora of suppliers offering a wide selection of products. For firms in search of dependable structural steel angle lines, Alibaba.com presents a platform to discover solutions that cater to your precise requirements. Whether your need is for a conventional angle line or bespoke machinery, Alibaba.com accommodates the full spectrum of demands.

The platform's user-friendly interface enables you to sift through options based on various criteria, including processing services provided by suppliers such as cutting, punching, bending, and welding; standards like ASTM or GB; applications from construction to industrial frameworks; grades from Q195 to A36; and surface treatments like hot-dip galvanizing or powder coating. This customization ensures that regardless of your project's scope or intricacy, you can locate equipment that fulfills your exact specifications.

Furthermore, Alibaba.com's dedication to secure transactions, exemplified by services like Trade Assurance, guarantees the protection of your investment until the completion of delivery. With more than two decades of expertise in online wholesale trade solutions, Alibaba.com streamlines the procurement of high-quality structural steel angle lines among its extensive offerings. This commitment has established Alibaba.com not merely as a marketplace but as a partner in global commerce, aiding businesses in realizing their expansion goals.

Frequently Asked Questions About Structural Steel Angle Lines

What distinguishes equal from unequal structural steel angles?

Equal angles are utilized when the angle's legs are identical in length, ensuring even load distribution. In contrast, unequal angles have legs of varying lengths, accommodating different load types and are used in structures requiring varied load-bearing on each side.

How does the structural steel grade impact its use?

The structural steel's grade defines its strength, ductility, and weldability. Higher-grade steels such as A36 or S235 are more robust and suitable for substantial construction, whereas lower-grade steels like Q195 or SS400 are prevalent in lighter applications.

What considerations should guide the choice between hot-dipped and pre-galvanized angles?

Hot-dipped galvanized angles provide superior corrosion protection, ideal for outdoor settings, while pre-galvanized angles offer adequate indoor protection. The decision hinges on the required level of corrosion resistance for the project.

Is it feasible to tailor structural steel angles for specific projects?

Absolutely, structural steel angles can be customized in dimensions, length, thickness, and processing services to align with a project's unique demands.

Why is surface treatment important when selecting a structural steel angle?

Surface treatments like galvanization or painting enhance a structural steel angle's durability and aesthetics by offering extra defense against environmental elements such as moisture and chemicals.

What industry standards for structural steel angles should I be aware of?

Structural steel angles should adhere to industry standards like ASTM, JIS, GB, or DIN to ensure they satisfy regulatory criteria and are safe and effective for construction use.

How can I ascertain if an angle is appropriate for corrosive environments?

To guarantee suitability for corrosive settings, opt for angles crafted from materials like stainless steel or galvanized steel, which inherently resist rust and oxidation.

What are the ideal applications for stainless steel angles?

Stainless steel angles are particularly well-suited for environments demanding corrosion resistance, such as marine settings or food processing facilities where cleanliness is paramount.

How is the load-bearing capacity of a structural steel angle determined?

The load-bearing capacity of a structural steel angle is contingent upon its size, thickness, grade, and the orientation relative to the applied load. Industry standards and guidelines should be consulted to select the appropriate angle size and grade.

What processing services are applicable to structural steel angles?

Structural steel angles can undergo a range of processing services, including cutting, punching, welding, bending, decoiling, and can be specified with details like ASTM, AISI, or EN.

Can I source eco-friendly structural steel angles?

Indeed, it is possible to procure eco-friendly structural steel angles. Suppliers may offer products fabricated from recycled materials or those manufactured without harmful substances.

How do hot rolling and cold forming differ in the production of structural steel angles?

Hot rolling involves shaping metal at elevated temperatures, resulting in angles with greater tensile strength but less precision in dimensions. Conversely, cold forming maintains more exact dimensions as it does not alter the metal's structure.

Can I find industry-specific structural steel angles on Alibaba.com?

Yes, Alibaba.com offers a broad array of products, including industry-specific items such as profiles or specialized angles. Buyers can refine search results to locate products that meet their industry or project-specific needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4