Explore the Versatility of Canon Traction Machines

Traction machines are integral components in modern engineering and construction, playing a pivotal role in various applications. Among these, canon traction machines stand out for their diverse designs and technological adaptations. These machines are crafted to cater to different needs, whether it's for compact spaces or to complement the minimalist aesthetics of a property.

Types and Technologies of Canon Traction Machines

The range of canon traction machines encompasses several types, each utilizing distinct technologies such as pneumatic systems, hydraulic operations, winding drums, and advanced traction mechanisms. This variety ensures that every functional requirement and industry standard can be met with precision.

Applications and Features

Canon traction machines are not limited to a single application. Their robust design enables them to be used in settings that require reliable lifting and moving solutions. With features that facilitate ease of use and efficiency, these machines are an essential tool for industries looking to streamline their operations.

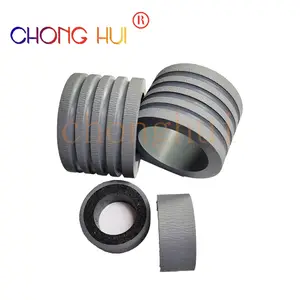

Materials and Durability

Durability is a cornerstone of canon traction machines, which are constructed from high-grade materials. Solid metals ensure longevity, while options like rustic leather add a touch of elegance without compromising functionality. The materials are chosen for their endurance and ability to withstand the demands of heavy usage.

Advantages of Canon Traction Machines

The advantages of using canon traction machines are manifold. They significantly reduce the time, effort, and labor involved in the manufacturing, assembly, and installation of electrical equipment. Their design allows for easy maintenance and adjustments, ensuring continuous operation and efficiency.

Electrical Connectivity and Maintenance

Canon traction machines are equipped with sophisticated electrical connectors that facilitate a seamless flow of current, essential for their operation. These connectors are designed for both permanent and temporary connections, allowing for flexibility in electrical circuit design. Maintenance is made simpler with the availability of compatible kits, ensuring that the machines remain in optimal condition.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4