Exploring the Versatility of CNC Gear Racks

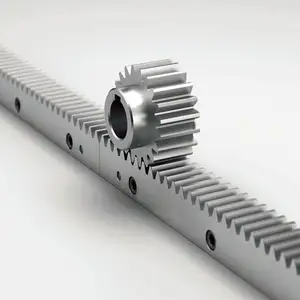

CNC gear racks are integral components in the translation of rotational motion into linear motion. This transformation is pivotal in various mechanical systems, enhancing both precision and efficiency. A CNC gear rack, paired with a cnc pinion gear, forms the fundamental rack and pinion cnc system, widely adopted in numerous applications due to its straightforward design and reliable performance.

Types and Features of CNC Gear Racks

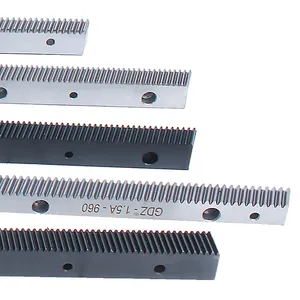

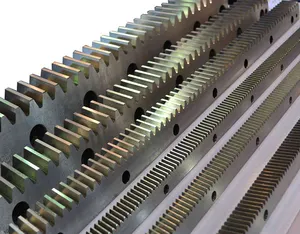

The diversity of CNC gear racks includes several types, each tailored for specific mechanisms and applications. The common variant, with straight teeth, aligns the axis of rotation with the tooth axis, ensuring standard motion transfer. In contrast, helical rack and pinion cnc systems feature helically twisted teeth, which align diagonally to the rotational axis. This design ensures continuous engagement, resulting in a smoother and quieter operation. The choice between these types hinges on the required efficiency and noise level of the machinery in question.

Applications Across Industries

The scope of cnc gear rack applications is vast, encompassing everything from simple toys to complex industrial machinery. They are pivotal in achieving horizontal and vertical movements, serving as stoppers and positioning mechanisms. In the realm of automation, cnc plasma rack and pinion systems are crucial for precise cutting operations. Similarly, nema 23 rack and pinion and nema 34 rack and pinion configurations are essential in customizing motion control for various CNC machines, including cnc router rack and pinion setups.

Material and Construction Advantages

CNC gear racks are designed to be compact, lightweight, yet highly rigid, which translates to responsive and reliable performance in demanding settings. The absence of length constraints allows for extensive adaptability in design, making them suitable for a wide range of machinery. Their structural simplicity also enables them to support heavy loads without compromising on precision or efficiency.

Choosing the Right CNC Gear Rack

Selecting the appropriate cnc gear rack is crucial for ensuring optimal performance of machinery. Factors such as load capacity, precision requirements, and environmental conditions play a significant role in determining the most suitable gear rack. For specialized applications, such as the rack and pinion z axis in 3D printers or the openbuilds rack and pinion systems in DIY CNC projects, understanding the specific needs of the operation is key to making an informed decision.

Conclusion

The CNC gear rack is a testament to the elegance of engineering simplicity, offering a robust solution for linear motion challenges across various industries. With the ability to accommodate a multitude of configurations, such as the joe's cnc rack and pinion or the x carve rack and pinion, these components are indispensable in the realm of precision motion. When sourcing for a CNC gear rack, it is essential to consider the specific requirements of your machinery to ensure seamless integration and operation.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4