Exploring the Utility of Cold Tapping Machines

The realm of industrial drilling embraces the cold tapping machine as a pivotal tool, designed to execute precise and efficient tapping operations. This category of machinery is integral to workshops and manufacturing environments, where creating threaded holes is a routine yet critical task.

Components and Construction

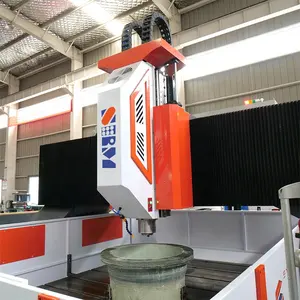

A cold tapping machine comprises several key components, each playing a vital role in its operation. The drill head, which houses the mechanism for the tapping process, is supported by a robust base. This base anchors the vertical column, a cylindrical structure that not only supports the drill head but also the machine's table and radial arm. The table, equipped with T-slots, facilitates secure clamping of workpieces, and can be found in various shapes, including round and rectangular designs. The radial arm, offering versatility, allows the drill head to maneuver with precision around the workpiece.

Types and Applications

Diverse in its variants, the cold tapping equipment category encompasses machines that cater to different materials and scales of operation. From creating threads in pipelines to intricate threading in metalworking, these machines are adaptable to a multitude of tasks. Their applications span across industries, including but not limited to, automotive, construction, and metal fabrication.

Features and Advantages

The efficiency of a thread tapping machine lies in its ability to produce clean, accurate threads without generating excessive heat or requiring substantial manual effort. This not only accelerates the production process but also minimizes operator fatigue. The precision-engineered parts ensure consistency in performance, making these machines a reliable component of any workshop's equipment arsenal.

Materials and Durability

Constructed from durable materials, the automatic tapping machine is built to withstand the rigors of heavy use. The choice of materials for each component is made with longevity and performance in mind, ensuring that the machine can maintain its precision over countless cycles of use.

Choosing the Right Machine

Selecting the appropriate industrial tapping machine requires an understanding of the specific requirements of the task at hand. Factors such as the material to be tapped, the size of the holes, and the production volume all play a crucial role in determining the most suitable machine for a given application.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4