Top categories

Wire Mesh

Stainless Steel

Alloy Steel

Non-ferrous Metal

Metals & Metal Products

Carbon Steel

Iron & Iron Products

About products and suppliers

The Essence of Steel Curved Beams

Steel curved beams are indispensable in the realms of construction and structural engineering, offering vital support and structure to an array of edifices, viaducts, and industrial frameworks. These components are engineered to withstand loads, counteracting bending and deflection—a prevalent challenge in traditional construction that often necessitates elaborate support systems. Their arched configuration enables them to cover larger expanses while preserving structural soundness, thus becoming a pivotal selection for designers and engineers aiming to optimize spatial efficiency and architectural versatility.

At its core, the function of a steel curved beam mirrors that of its linear counterpart: to sustain the imposed load without surpassing its stress capacity. Yet, their curved form not only fulfills this purpose but also enhances visual allure. The beams' curvature is typically realized through a synthesis of rolling and bending techniques, tailored to meet the unique demands of a given project. This adaptability permits a broad spectrum of uses, ranging from underpinning the canopy of a curved edifice to crafting a graceful balustrade that traces a staircase's curve.

Steel curved beams boast adaptability and can be seamlessly incorporated into a multitude of design aesthetics, be it contemporary, industrial, or classical. They transcend mere functionality, also acting as a central design feature that opens avenues for artistic innovation and avant-garde architectural concepts. Crafting these beams demands meticulousness and proficiency to ensure they fulfill the dual mandates of structural support and visual charm.

Varieties of Steel Curved Beams

A diverse array of steel curved beams is at hand to cater to the multifaceted requirements of construction endeavors:

-

I-Beams and W-Beams: These prevalent steel beam types offer exceptional strength and adaptability. Their configuration renders them suitable for a vast array of structural roles, from horizontal supports to vertical pillars.

-

H-Beams: Distinguished by their expansive flanges and tapered webs, H-beams are especially apt for heavy-duty tasks where broad support bases are imperative.

-

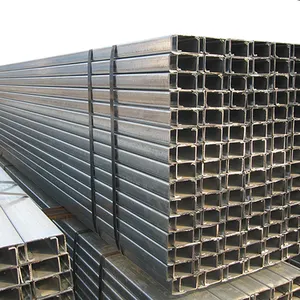

Channel Beams: Primarily employed for lighter load-bearing functions, channel beams feature a characteristic C-shaped profile. Their installation simplicity and versatility make them a popular choice in various structural components.

-

Box Beams: Characterized by their rectangular or box-like cross-section, these beams provide formidable strength and are frequently utilized in scenarios demanding deep beams or substantial load-bearing prowess.

-

Compound Beams: Constructed by fusing two or more simple members of disparate materials, these beams form a unified structural entity capable of extending across vast distances with reduced weight.

Selecting the Right Steel Curved Beam

When choosing Steel Curved Beams for any construction initiative, a multitude of factors must be weighed to guarantee aptness and operational efficiency:

-

Material Grade: The steel's grade dictates its tensile robustness and corrosion resistance. A superior grade ensures enhanced structural integrity, a critical aspect for the safety of any construction application.

-

Beam Size and Shape: The beam's dimensions must be commensurate with the specific loads it is intended to bear. Its shape also influences the ease with which it can be integrated with other structural components.

-

Curvature and Span: The design of the curvature should not only be aesthetically pleasing but also maintain structural reliability. The span should be suitable for the intended space, obviating the need for extra supports.

-

Application: The beam's intended use—be it for roofing, bridge construction, or other purposes—will affect the required type of curvature.

-

Installation Requirements: Certain projects may necessitate bespoke installation methods; suppliers should be equipped to fulfill these specifications.

Steel Curved Beams on Alibaba.com

Alibaba.com serves as a premier global marketplace, bridging businesses with an extensive assortment of Steel Curved Beams suitable for myriad industrial uses. With a vast selection from global suppliers, Alibaba.com streamlines the process of locating the precise beam to match your criteria—whether you're in search of a standard model for a construction project or a bespoke solution for unique demands.

Alibaba.com is not only lauded for its extensive inventory but also for its commitment to secure transactions, exemplified by services such as Trade Assurance. This commitment guarantees the protection of your purchase until the delivery is finalized. Moreover, Alibaba.com's platform is crafted with user-friendly features that facilitate communication in local dialects and mobile-compatible purchasing options, thereby easing international commerce for businesses in motion.

Engaging with Alibaba.com affords businesses access to premium-quality Steel Curved Beams and leverages the platform's expertise in global B2B trade. This synergy positions Alibaba.com as an exemplary source for acquiring structural steel products that conform to your project's detailed specifications and logistical needs.

Frequently Asked Questions on Steel Curved Beams

What are the primary uses of steel curved beams?

Steel curved beams are highly versatile, finding utility in a range of applications such as construction for edifices, infrastructure projects like bridges and tunnels, automotive manufacturing for vehicle frameworks, and as design elements in creative ventures.

How do steel curved beams' strength and durability stack up against straight beams?

Thanks to their curvature, steel curved beams are adept at more evenly distributing loads, potentially resulting in a structure that is lighter yet equally capable of bearing weight as its straight-beamed counterparts.

What considerations are paramount when selecting a steel curved beam for a project?

In the selection of a steel curved beam, it is essential to contemplate the necessary load-bearing capacity, material robustness, curvature specifications, environmental conditions of the beam's application (such as weather exposure or corrosive elements), and adherence to industry norms.

Are there established industry standards for steel curved beams that businesses should recognize?

Indeed, industry standards like ASTM (American Society for Testing and Materials) codes stipulate the criteria for steel beams in construction and manufacturing, ensuring quality and safety.

Is it possible to tailor steel curved beams to specific shapes or dimensions?

Suppliers on Alibaba.com can accommodate requests for steel curved beams in custom configurations and sizes to meet the precise needs of your project.

What finishing options are available for steel curved beams?

Steel curved beams can be finished in various ways, including galvanization, painting, powder coating, or they can be left in their raw state, depending on the aesthetic and functional requirements of the project.

How is the appropriate load capacity for a steel curved beam determined?

The load capacity of a steel curved beam is ascertained by its design, the properties of the material, and the nature of the loads it will support. Consulting with industry experts or suppliers is crucial to identify the suitable beam type and specifications.

What maintenance insights should businesses have regarding steel curved beams?

Steel curved beams necessitate regular inspections and maintenance to ensure their longevity and optimal performance. The maintenance schedule and procedures vary based on the conditions under which the beam is utilized.

How does the cost of a steel curved beam compare to that of a straight beam?

The cost of a steel curved beam is influenced by various factors, including the grade of the material, beam profile, finishing, customization requirements, and quantity. Generally, due to the complexity of their manufacturing, they may command a higher price than straight beams.

Are eco-friendly alternatives available for steel curved beams?

Eco-friendly options for steel curved beams may be offered, contingent on the supplier's material sourcing and production practices. Some suppliers may provide beams composed of recycled materials or utilize energy-efficient manufacturing techniques.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4