Understanding Industrial Deburring Machines

Industrial deburring machines are specialized equipment designed to eliminate burrs or rough edges from materials like metal, plastic, and wood. These machines play a crucial role in ensuring the accuracy and safety of the final products by removing any unwanted protrusions that could impact functionality. Deburring is a critical finishing step in industries like automotive, aerospace, electronics, and construction.

The core principle of industrial deburring machines involves applying controlled force or abrasion to refine the workpiece's surface by eliminating excess material. Various techniques, such as tumbling with media, abrasive blasting, or using wire brushes, can achieve this based on the machine's design. Precision and consistency are key during operation, leading to the integration of advanced features like speed control, pressure adjustment, and media containment.

Industrial deburring machines cater to diverse production scales, ranging from small workshops needing compact units for occasional tasks to large manufacturing plants with high-volume demands. Their versatility in handling different materials and shapes makes them indispensable in any production environment, enhancing surface finish, removing burrs, and preparing surfaces for subsequent processes or assembly.

Varieties of Industrial Deburring Machines

Industrial deburring machines are available in several types to address specific deburring requirements across industries:

-

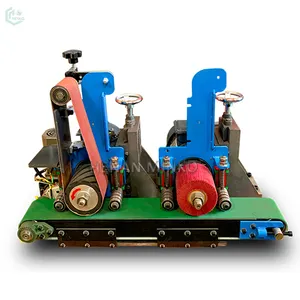

Belt Sanders: These machines utilize continuous sandpaper loops around two drums to remove material from workpiece surfaces, commonly used in metal fabrication and woodworking for substantial stock removal.

-

Rotary Burr Cutters: Equipped with rotating cutting tools, these machines excel in precision deburring for metalworking applications, ideal for heavy-duty tasks due to their robust design.

-

Handheld Deburring Tools: Portable tools suitable for smaller jobs or difficult-to-reach areas, commonly employing blades or abrasive pads to eliminate burrs.

-

Portable Deburring Machines: Designed for on-site use or repair shops, these lightweight and compact machines offer easy transportability to various locations as needed.

-

Electric Deburring Tools: Power-driven tools versatile enough to handle various deburring tasks on materials such as steel, aluminum, and stainless steel.

Selecting the Right Industrial Deburring Machine

Choosing the appropriate industrial deburring machine for your business necessitates a thorough evaluation of several factors:

-

Material Compatibility: Ensure the machine is suitable for the specific materials you work with; for instance, a machine with abrasive wheels designed for hard metals might be necessary for deburring steel parts.

-

Deburring Requirements: Consider the precision level required for your deburring process; some machines offer enhanced control for intricate parts with higher precision.

-

Throughput: Evaluate the volume of parts needing processing as machines vary in capacity to handle large quantities or multiple pieces simultaneously.

-

Available Space: Measure the installation area to ensure the machine fits comfortably while allowing easy access for operation.

-

After-sales Service: Opt for suppliers offering comprehensive after-sales services like online or video technical support to ensure operational continuity.

Considering these factors alongside essential components like motors and PLCs enables informed decision-making aligned with operational requirements and budget constraints.

About Industrial Deburring Machines on Alibaba.com

Alibaba.com serves as a global marketplace connecting businesses with a wide array of industrial deburring machines suitable for various metal workpiece finishing needs. With a diverse range from global suppliers, Alibaba.com simplifies finding the right machine to meet industrial demands, offering customized solutions. Whether in manufacturing plants or machinery repair shops, Alibaba.com provides access to numerous options capable of handling materials like stainless steel, carbon steel, and aluminum alloy.

The platform's commitment to streamlining global trade is evident through its user-friendly interface supporting local languages and mobile accessibility. Additionally, Alibaba.com's Trade Assurance service enhances security by safeguarding payments until delivery confirmation, ensuring a secure purchasing experience from international suppliers.

By selecting Alibaba.com for wholesale industrial deburring needs, businesses benefit from competitive pricing without compromising quality or variety. Suppliers offering after-sales support, including online assistance and video technical support, empower businesses to invest confidently in machinery promising operational ease and high productivity.

Frequently Asked Questions about Industrial Deburring Machines

What is the purpose of an industrial deburring machine?

An industrial deburring machine is utilized to eliminate burrs and refine surfaces on metal workpieces, crucial for precision machining and efficient assembly in various industries.

How does an industrial deburring machine operate?

Typically, an industrial deburring machine employs rotating abrasive bits or blades to remove material from metal workpiece edges and surfaces, resulting in clean and smooth finishes.

Can industrial deburring machines handle diverse materials?

Yes, industrial deburring machines are designed to process various materials like steel, aluminum, stainless steel, and softer plastics, each requiring specific tools and attachments.

What are the essential features to look for in an industrial deburring machine?

Key features include operational efficiency, accuracy, durability, material versatility, safety features, and customized support like OEM or ODM services.

Is customization possible for industrial deburring machines?

Many suppliers offer customization options such as OEM, ODM, or OBM services, allowing businesses to tailor machines to their specific requirements and applications.

What materials are commonly used in constructing industrial deburring machines?

Industrial deburring machines are typically constructed using robust materials like steel or stainless steel to ensure longevity and reliability in demanding operations.

How can one select the appropriate abrasive bit for a deburring machine?

Choose abrasive bits based on the material being deburred, required abrasive type (e.g., silicon carbide, aluminum oxide), and compatibility in size and shape with the machine's specifications.

What safety considerations should be taken when using an industrial deburring machine?

Safety measures include wearing proper personal protective equipment (PPE), adhering to manufacturer guidelines for tool use and safety protocols during operation, and ensuring operators are trained in safe handling practices.

What maintenance is necessary for industrial deburring machines?

Regular maintenance typically involves checking and cleaning abrasive bits or blades, lubricating moving parts as needed, and inspecting for wear or damage.

Can industrial deburring machines accommodate both small and large workpieces?

Yes, machines are available to handle a range of sizes, from small pieces to large workpieces. Choose the machine size based on the maximum item size requiring deburring.

How can one ensure seamless integration of an industrial deburring machine with existing manufacturing processes?

Ensure compatibility by selecting a machine that can manage the size and weight of workpieces and offers the connectivity required in your production setup.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4