Dismantling Joint Overview

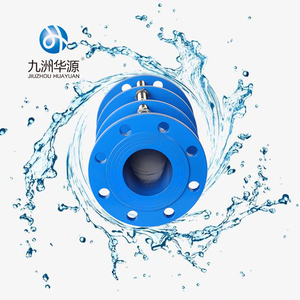

A dismantling joint is a vital component within pipe systems, facilitating the installation and removal of sectional components such as valves, pumps, and flow meters. This mechanical device is essential for the maintenance and modification of pipeline systems, ensuring a secure and reliable connection while allowing for easy disassembly when necessary.

Types and Materials

The materials used for dismantling joints vary, with each type serving a specific purpose. DI dismantling joints (ductile iron) are known for their strength and durability, making them suitable for high-pressure applications. Conversely, CI dismantling joints (cast iron) are often utilized in less demanding environments. Advanced options like the VJ dismantling joint (Viking Johnson) and AVK dismantling joint provide specialized solutions for complex systems.

Applications and Features

The application of a dismantling joint is diverse, ranging from water treatment facilities to industrial manufacturing plants. A dismantling joint with butterfly valve is commonly used to achieve precise flow control, while a restrained dismantling joint ensures stability in systems where thrust forces are present. The flange dismantling joint is another variant, designed to connect flanged components and facilitate easy access for repairs or inspections.

Advantages of Dismantling Joints

The primary dismantling joint purpose is to deliver flexibility and convenience in system maintenance. The compact dismantling joint is particularly beneficial in tight spaces, allowing for straightforward installation and removal without the need for extensive modifications to the surrounding infrastructure. Additionally, the dismantling coupling serves as a crucial pivot point, accommodating angular deflection and linear movement, which can be essential in preventing pipeline stress.

Selection Considerations

When selecting a dismantling joint, factors such as the type of fluid, pressure requirements, and environmental conditions are paramount. For instance, the dj400 romac and romac dismantling joint are engineered to withstand varying pressures and temperatures, making them suitable for a wide range of applications. The smith blair dismantling joint is another example, offering robust performance in various settings.

Conclusion

In conclusion, the dismantling joint is an indispensable component in modern piping systems, providing a combination of strength, flexibility, and ease of maintenance. Whether it is a dismantling joint pipe for industrial use or a flange adaptor and dismantling joint for a municipal water system, the right choice of dismantling joint can significantly enhance the operational efficiency and longevity of pipeline networks.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4