EVA Machine: An Overview

Ethylene-vinyl acetate (EVA) machines play a pivotal role in the manufacturing sector, facilitating the production of a wide array of EVA products. These machines, known for their versatility, are essential in creating everything from automotive parts to footwear. The eva injection moulding machine is particularly significant in the industry, allowing for precise shaping of EVA into various items through a high-precision process.

Types and Applications of EVA Machinery

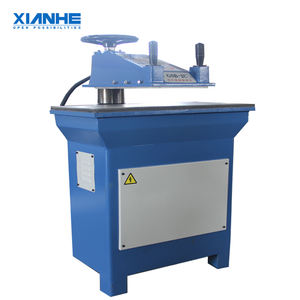

The spectrum of EVA machinery includes several types, each serving a specific function. The eva foam cutting machine is designed for precision cutting of EVA foam into numerous shapes and sizes, commonly used in packaging and cushioning materials. On the other hand, the eva slipper making machine and eva sole making machine are specialized for the footwear industry, streamlining the production of comfortable and durable shoes. These machines are adept at handling the material's unique properties, such as flexibility and cushioning.

Features and Materials in EVA Processing

EVA machines are engineered to work with the distinct characteristics of EVA material, which is known for its durability, flexibility, and resistance to cracks and UV radiation. For instance, the eva foam laser cutter utilizes advanced technology to cut EVA foam with extreme precision without compromising the material's integrity. Similarly, the eva lamination machine applies layers of EVA with other materials, enhancing the product's properties for specific applications.

Advantages of Using EVA Machines

Utilizing EVA machines in production offers numerous advantages. These machines are capable of handling the material's low thermal conductivity, making them suitable for products that require insulation properties. Moreover, EVA's shock absorption capabilities are unmatched, as seen in protective packaging and cushioning applications. The eva foam machine is particularly adept at producing materials that can withstand significant stress, supporting weights many times their own.

Innovations in EVA Machinery

Innovation in EVA processing technology has led to the development of machines like the eva chappal making machine and eva shoe making machine, which cater to the booming footwear industry. These machines have revolutionized the production process, enhancing efficiency and precision. Additionally, the integration of cnc eva foam technology has allowed for computer-controlled machining, offering unparalleled accuracy and design flexibility in EVA foam products.

Conclusion

In conclusion, EVA machines are integral to various industries, known for their ability to mold, cut, and laminate EVA material efficiently. From creating intricate designs with an eva foam cnc machine to mass-producing footwear with an eva injection shoes machine, the capabilities of EVA machinery are essential to modern manufacturing processes. As the demand for EVA products continues to grow, the evolution of these machines will undoubtedly progress, driving innovation and efficiency in production lines worldwide.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4