Introduction to FFC Cables

Flexible Flat Cables, commonly known as FFC cables, are a pivotal component in modern electronic connectivity. These cables are designed to enable high-density connections between multiple electronic devices, offering a compact and flexible solution. The flexible flat cable is widely utilized in various applications, from intricate medical devices to consumer electronics, providing a reliable and efficient means of data and signal transmission.

Types and Applications

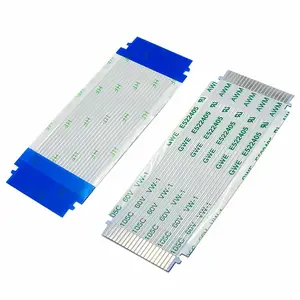

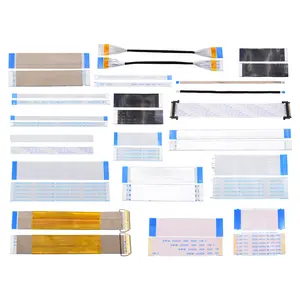

The versatility of FFC cables is reflected in their various types, each tailored for specific applications. The FFC FPC connector variety is often employed in situations requiring a durable yet flexible connection, such as in portable electronic devices. On the other hand, the AWM 20624 cable 80c 60v vw-1 is recognized for its ability to withstand high temperatures and voltage conditions, making it suitable for automotive and industrial applications. The AWM 20706 105c 60v vw1 variant further extends this durability to even more demanding environments.

Features and Materials

FFC cables are constructed from high-grade materials that ensure signal integrity and flexibility. The conductive tracks are typically made from tinned copper, encapsulated within a flexible insulating film. This construction not only facilitates the cable's bending and folding but also safeguards against environmental factors such as moisture and extreme temperatures. The AWM 20624 and AWM 20706 standards denote the cables' compliance with specific material and performance criteria, ensuring their reliability in various operating conditions.

Advantages of FFC Cables

The primary advantage of FFC cables lies in their flexibility, which significantly reduces space constraints within electronic assemblies. This flexibility, coupled with the cable's thin profile, allows for more compact device designs. Additionally, the use of flat flex connectors and flat flex cable connectors simplifies the installation process, reducing the risk of connection errors and saving time in assembly operations. The standardized ffc cable connector systems also contribute to the ease of maintenance and replacement, enhancing the overall efficiency of electronic manufacturing and repair processes.

Choosing the Right FFC Cable

Selecting the appropriate FFC cable for a specific application involves considering factors such as the number of conductors, pitch size, length, and the type of connectors, such as the FFC cable connector or flat flexible connector. It is crucial to match the cable's specifications with the operational requirements of the device, ensuring optimal performance and longevity. For specialized applications, cables like the AWM 20624 80c 60v vw-1 or 20624 cable 80c 60v vw-1 provide additional assurances against harsh conditions.

Conclusion

In conclusion, FFC cables offer a reliable and adaptable solution for high-density electronic connections. With a range of types and specifications available, these cables meet the diverse needs of various industries, contributing to the advancement of electronic design and functionality. When integrating FFC cables into electronic systems, it is essential to consider the specific requirements of the application to ensure a successful and efficient connection.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4