The Concept of Foam Cutting Blades

Foam cutting blades are specialized implements crafted for the precise cutting of foam materials. These tools find utility across diverse sectors including manufacturing facilities, construction sites, packaging enterprises, and even in domestic applications for DIY projects. The distinctive characteristics of foam, such as its lightweight nature and malleability, render it a widely adopted material in various domains. Professionals with a demand for meticulous and accurate cuts rely on foam cutting blades to deliver high-caliber end products.

The operational principle of foam cutting blades entails exerting force on the foam material, prompting the blade to cleave through its structure. Depending on variables like the blade type and the density of the material, distinct cutting methods may be employed. For instance, certain blades oscillate rapidly to create a sawing motion, while others move continuously to achieve a smoother cut. The selection of blade type and cutting technique hinges on the specific demands of the task at hand, encompassing the type of foam material and the requisite dimensions.

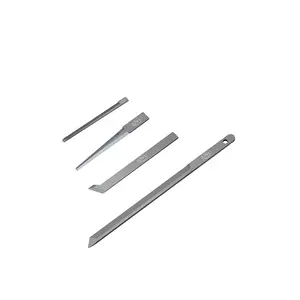

Foam cutting blades are fashioned from materials such as steel, stainless steel, or ceramics. Their design features can vary significantly based on the intended application—some may resemble saw teeth for aggressive cutting, while others sport a sleek, blade-like edge for more delicate tasks. The efficacy and durability of these blades are contingent on factors like material composition, blade structure, and the cutting environment.

Varieties of Foam Cutting Blades

The array of foam cutting blades available is extensive, with each type tailored to address specific requirements within diverse industries. Here is a brief overview of some common variants:

-

Oscillating Blade Contour Cutter: This blade type features teeth on both sides and utilizes rapid back-and-forth movements to cut through materials. It is commonly employed for intricate tasks such as shaping elaborate forms or making precise cuts in thin materials.

-

Sponge Cutting Machine Blade: Specifically designed for cutting sponge and foam materials, these blades often incorporate a heated wire or blade for seamless cuts. They prove ideal for applications in product packaging, insulation, and soundproofing.

-

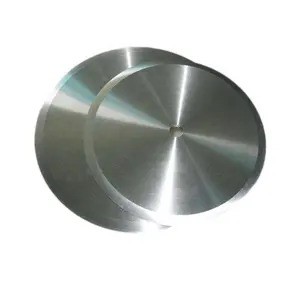

Ring Knife Machine Blade: Ring knife machines feature a blade comprising sharp circular blades attached to a handle. The user manually rotates the blade around a material to facilitate cutting. This blade type is frequently used in construction for insulation or roofing material cutting.

-

Fast Wire Contour Cutter: Employing a wire instead of a conventional blade, these cutters excel in producing straight or angled cuts with minimal material distortion. They find common use in construction for cutting rigid foam insulation boards, as well as in artistic and sign-making endeavors that demand precision.

While each type serves distinct purposes, they all share a fundamental aim of effortlessly and accurately cutting soft materials.

Guidelines for Selecting Foam Cutting Blades

The meticulous choice of foam cutting blades is pivotal for achieving immaculate cuts and maximizing operational efficiency. When selecting these blades for your business requirements on Alibaba.com, take into account the following aspects:

-

Blade Material: The blade material should align with the types of foam being cut. For instance, carbon steel blades may suffice for general cutting but could be inadequate for intricate or high-density cuts that might benefit from diamond or hot wire blades.

-

Blade Edge: The sharpness of the blade edge impacts its cutting precision, particularly in sectors like electronics or medical supplies that demand exactitude.

-

Blade Size: Verify that the blade dimensions match your cutting machinery's specifications to avoid imprecise cuts or equipment damage.

-

Heat Conductivity: Hot wire blades are effective for dense materials but necessitate specialized equipment. Evaluate if your operations can support this blade type.

By meticulously evaluating these factors against your specific application requisites, you can make an informed decision that strikes a balance between performance, cost-efficiency, and operational durability.

Insights into Foam Cutting Blades on Alibaba.com

Alibaba.com serves as a vast marketplace where businesses seeking premium wholesale foam cutting blades can explore a broad selection tailored for various purposes. With a track record spanning over two decades in connecting suppliers with buyers worldwide, Alibaba.com has cemented its reputation as a dependable platform for efficiently sourcing commercial supplies. The platform's extensive product range encompasses options customized for diverse industries such as advertising firms, garment establishments, construction sites, and more.

The convenience offered by Alibaba.com transcends product diversity to encompass user-friendly features designed to streamline transactions across desktop and mobile platforms. Furthermore, Alibaba.com's Trade Assurance service furnishes an additional layer of security by safeguarding payments until satisfactory order fulfillment is confirmed. This commitment to seamless trade experiences underscores why businesses rely on Alibaba.com for sourcing their foam cutting blade requirements.

By leveraging Alibaba.com's global outreach, comprehensive product catalogs spanning various categories, and its dedication to empowering small and medium-sized enterprises through online trade solutions, companies can confidently equip themselves with the appropriate foam cutting blades to meet their unique needs while capitalizing on international trade opportunities facilitated by the platform.

FAQs Regarding Foam Cutting Blades

What types of foam cutting blades are suitable for industrial applications?

Several foam cutting blade types are tailored for industrial use, including oscillating blades, rotary blades, hot wire blades, and ring knife blades. Each blade is designed for specific foam materials and cutting tasks.

How should I select the appropriate blade for my foam cutting machine?

The selection of the right blade for your foam cutting machine hinges on the machine's specifications, the type of foam material to be cut, and the precision requirements for your applications. Consider aspects such as blade material, coating, and sharpness.

Can customized foam cutters with specific shapes be found on Alibaba.com?

Yes, numerous suppliers on Alibaba.com offer customized services such as OEM, ODM, and OBM to enable businesses to source tailor-made foam cutters aligned with their specific requirements.

What materials are commonly used in manufacturing foam cutting blades?

Foam cutting blades are typically crafted from materials like carbon steel, stainless steel, and high-speed steel (HSS) due to their durability and capacity to maintain sharp edges during operation.

Are there foam cutting blades suitable for both manual and CNC machines?

Absolutely, foam cutting blades are designed to be compatible with various machine types, encompassing handheld, oscillating, rotary, and hot wire cutters, catering to both manual and CNC-operated machines.

What factors should be considered when selecting a blade for different foam materials?

When choosing a blade for foam materials, factors like blade material, size, and design should be taken into account. For example, hot wire blades are well-suited for cutting rigid foam due to their precise and clean cuts, whereas oscillating blades are preferable for softer foams to prevent damage.

How can I prolong the lifespan of a foam cutting blade?

To extend the lifespan of a foam cutting blade, it is advisable to regularly clean the blade to eliminate any residue that could impact its performance and store the blade appropriately when not in use.

Are there blade options suitable for both small-scale and large-scale foam production?

Absolutely, Alibaba.com's network comprises suppliers offering a wide array of blades suitable for operations of varying scales, be it small-scale endeavors or large industrial production lines.

Are there environmentally sustainable options for foam cutting blades?

While the level of environmental sustainability may vary by material, certain blade options are designed to minimize waste or possess characteristics conducive to recycling at the end of their lifecycle.

What safety precautions should be observed when using foam cutting blades?

When employing foam cutting blades, it is imperative to wear appropriate personal protective equipment (PPE) and adhere to safe operating practices to prevent accidents and injuries.

How can I ascertain if a foam cutting blade is compatible with my machine?

To verify compatibility, review the blade's specifications such as size, arbor size, material hardness, and suitability for your machine's cutting requirements.

Are there any post-purchase services provided with foam cutting blade acquisitions?

Post-purchase services vary among suppliers but may encompass offerings like video technical support, field maintenance and repair services, or online assistance.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4