Understanding Harmonic Drive Gears

A harmonic drive gear is an intricate component widely utilized in high-precision mechanical applications. This sophisticated piece of engineering is designed to offer superior mechanical advantages in various systems, primarily focusing on motion control and power transmission. Its unique construction allows for the delivery of high torque while maintaining compact dimensions, making it a preferred choice in space-constrained applications.

Components and Functionality

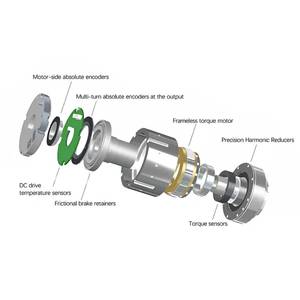

The core of a harmonic drive consists of three essential parts: the flexspline, the circular spline, and the wave generator. Each plays a pivotal role in the gear's operation. The flexspline is a flexible metal cylinder that deforms slightly to engage with the rigid circular spline, while the wave generator, typically an elliptical disc, orchestrates the synchronized movement of these components. This interaction results in the precise control of rotational movement, a defining characteristic of the strain wave gear.

Applications and Versatility

Harmonic drive gears are integral to sectors that demand exact motion and reliability. Their application spans from robotics, where precision gearboxes are crucial, to aerospace and defense mechanisms requiring high torque gears with minimal backlash. The adaptability of these gears to various environments without compromising performance is a testament to their robust design and the meticulous engineering behind them.

Material Composition and Features

The materials used in a harmonic drive are selected for their durability and resistance to wear. High-grade steel and specialized alloys are commonly employed to ensure the longevity and consistent performance of the gears. The precision in manufacturing is evident in the seamless integration of components, which is vital for maintaining the gear's high reduction ratios and ensuring its smooth operation.

Advantages of Harmonic Drive Gears

The advantages of employing a harmonic drive gear in mechanical systems are multifaceted. They offer exceptional positional accuracy and repeatability, essential for automation and control systems. Moreover, their design inherently provides high torque capacity while maintaining a compact footprint. The efficiency of these gears is further enhanced by their low energy consumption and reduced maintenance requirements, making them a sustainable option for long-term applications.

Selecting the Right Harmonic Drive Gear

When sourcing a harmonic drive gear on Alibaba.com, it is crucial to consider factors such as the gear's rated torque, operational speed, and the intended duty cycle. Alibaba.com facilitates access to a diverse range of suppliers, ensuring that you can find a gear that aligns with your specific requirements. The platform's around-the-clock operation simplifies the procurement process, allowing for seamless transactions and efficient communication with suppliers.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4