Jumper cable clamps are indispensable tools for drivers and automotive professionals alike, serving as a lifeline for vehicles with depleted batteries. These clamps facilitate the revival of a vehicle's battery by creating a bridge for electrical current to flow from a donor battery, enabling a jump-start. The primary keyword product, jumper cable clamps, is a broad term that encompasses various types of clamps designed for different vehicular needs and scenarios.

Types and Characteristics of Jumper Cable Clamps

There is a diverse array of jumper cable clamps available, each with unique characteristics to suit different applications. For instance, heavy duty jumper cable clamps are designed for larger vehicles with higher power requirements, such as trucks and buses, providing a larger contact area and stronger grip to handle the greater electrical current. On the other hand, jumper cable replacement ends are available for those who need to repair or replace existing clamps. For specialized applications, there are booster cable clamps with built-in voltage meters to help monitor the power transfer during the jump-start process. Each type is tailored to meet specific requirements, ensuring that there is a suitable clamp for every situation.

Structure and Operation of Jumper Cable Clamps

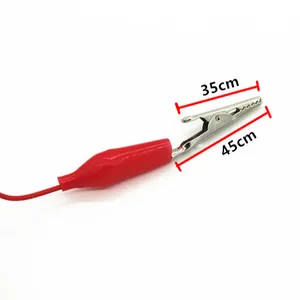

The structure of jumper cable clamps is a testament to their functionality. Each clamp typically consists of a pair of jaws, a spring mechanism, and insulated handles. The jaws, often made of high-conductivity metals like copper or brass, are designed to firmly attach to battery terminals. The spring mechanism ensures that the jaws maintain a secure grip, preventing disconnection during use. The insulated handles, usually made of rubber or plastic, protect the user from electric shocks. In operation, the jaws must make a solid contact with the battery posts, which is critical for a safe and effective jump-start. The spring mechanism's tension can be adjusted in some models to accommodate different battery sizes, enhancing the versatility of the clamps.

Materials and Their Properties

The choice of materials for jumper cable clamps is crucial for their performance. Copper is often used for the conducting parts due to its excellent electrical conductivity, which ensures minimal resistance and maximum current flow. The clamps may also be made of steel for added strength, with a copper or brass plating to prevent corrosion and ensure good conductivity. Insulators such as PVC or rubber are used for the handles to provide electrical insulation and user comfort. These materials are selected not only for their functional properties but also for their durability, ensuring that the clamps can withstand the rigors of regular use.

Business Usages and Applications

In the business realm, jumper cable clamps are vital in automotive repair shops, transportation companies, and emergency services. They are used to quickly restore power to vehicles, which is essential for maintaining fleet operations and reducing downtime. In automotive repair shops, these clamps are part of diagnostic equipment, helping technicians test and charge batteries. The reliability of heavy duty booster cable clamps is particularly valued in commercial settings where heavy machinery or large vehicles require frequent jump-starts. These clamps create business value by ensuring that vehicles and equipment are operational with minimal delay, contributing to overall efficiency and productivity.

Functions and Tasks

The primary function of jumper cable clamps is to transmit electrical current from one battery to another. They are designed to clamp onto battery terminals securely, maintain a stable connection, and withstand the electrical load during a jump-start. Some clamps come with additional functionalities, such as built-in circuitry to prevent overcharging or short circuits, enhancing the safety and efficiency of the jump-start process.

Distinctive Features and Capabilities

Jumper cable clamps stand out from other electrical connectors with features tailored for jump-starting vehicles. High-quality clamps have color-coded handles for easy identification of positive and negative terminals, reducing the risk of incorrect connections. Some feature a serrated interior surface for a better grip on the battery posts, while others have a swivel design to allow for flexible positioning. These features are designed to provide a user-friendly experience and to set the product apart from competitors.

Benefits and Positive Outcomes

The benefits of using quality jumper cable clamps are manifold. They ensure a reliable start, which is crucial in emergency situations. The robust construction of heavy duty jumper cable ends means they can endure repeated use, offering long-term reliability. For businesses, the use of these clamps can mean the difference between a vehicle running on schedule or being out of service, directly impacting operational efficiency and profitability.

How to Use, Choose, Clean, Maintain, and Install

Using jumper cable clamps effectively involves opening the clamps and attaching them securely to the corresponding battery terminals, ensuring a firm connection without causing damage to the battery posts. When choosing the right clamps, consider the type of vehicles you'll be working with and the conditions in which they'll be used. For cleaning and maintenance, disconnect the clamps, clean with a wire brush to remove corrosion, and inspect for wear. Installation of replacement clamps typically involves attaching the clamp ends to the cables using crimping or soldering methods, depending on the design.

Target Audience and Meeting Needs

The target audience for jumper cable clamps includes automotive professionals, fleet managers, and individual vehicle owners. Each product is designed to meet the specific needs of these groups, whether it's the durability required by a professional mechanic or the ease of use needed by a casual driver. By understanding the preferences and requirements of these diverse users, manufacturers can tailor their products to better serve their target market.

How do I ensure the compatibility of jumper cable clamps with my vehicle?

Ensuring compatibility involves checking the clamp size, the type of insulation, and the connection type against your vehicle's requirements. Most jumper cable clamps are designed to be universally compatible, but for larger vehicles or those with unusual battery terminals, specialized heavy duty jumper cable ends may be necessary. Always verify the specifications of the clamps with your vehicle's battery terminal size and type.

What safety features should I look for in jumper cable clamps?

Safety is paramount when dealing with electrical components. Look for clamps with strong, non-slip insulating handles, a robust spring mechanism for a secure connection, and materials that are resistant to corrosion. Additionally, clamps should have a good grip pattern to ensure a solid connection to the battery posts, minimizing the risk of sparks or short circuits.

How do I properly maintain and store jumper cable clamps to extend their lifespan?

Proper maintenance involves regular cleaning with a wire brush to remove corrosion and dirt. Inspect the insulation for any cracks or wear and replace if necessary. When storing, keep the clamps in a cool, dry place to prevent rusting. Coiling the cables neatly without kinking will also help prevent damage to the wires inside. Lastly, it's wise to periodically check the tension of the spring in the clamps to ensure they still provide a strong, secure connection.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4