A Highly Automated And Flexible 6T 4 Axis Servo Driven Stretching And Bending Machine

High Production Capacity 3 Layers Air Bubble Film Sheet Making Machine

Neoden K1830 LED High Speed 66 Feeders 8 Heads Smt Smd Pick And Place Machine Pcb Assembly Line

Led Strip Light Profile Lighting Channel Aluminum With Water Wave Pc Diffuser 15 Powder Coating 80 Black Chandelier Black Circle

Manufacturing 2 2 Layers Air Bubble Film Sheet Making Machine Production Line

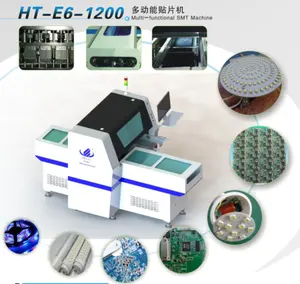

ICT801 Full Automatic SMD SMT Production Line SMT LED TV Bulb Lamp Lights Assembly Line Machine, SMT Line

Neoden Pick and Place Automatic LED Bulb LED Light Assembling Line PCB Smt Production Line

Fully Automatic SMT Production Line for Mobile Phone and LED Light Assembly Machine Line

LED TV Making Machine LED Light Lamp Production Machine Smartphone Assembly Line

led light making machine SMT production line

PC LED Strip Light Cover Lamp Production Line / Making Machine

Long Service Life Customized Automatic LED Assembly Line Panel Light Production Line

Hot sale polycarbonate sheet production line T5 T8 LED tube light making machine manufacturer Beierman factory good price

Automatic led bulb production line/led light assembling line/SMT machine

High efficiency LED bulb production line led bulb fully automatic production line led light bulb production line

led lamp manufacturing machine led bulb assembly machine led light production line

Automatic Led bulb production line led light assembly line L8

Sell & Buy Cheap YV100XG used smt machine for Yamaha used pick and place machine LED smt machine Light Assembly production line

LED Street light TV assembly line electric welding machine production line

SMT Pick and Place Machine 6 Heads Surface Mounter for SMT Production Line LED Light Assembly Line

LED Bulb Production Line Machine Manufacturing LED Light Assembly Line for LED Strips Making

led strip extruder machine led silicone light strip extruder making machine 2835 5730 led light strip coating production line

High Quality Electronic Production / led light assembly line / Antistatic Assembly Line

Full Automatic PCB LED Bulb Light Assembly Equipment TV SMT AI Production Line SMD SMT Line And Machine Manufacture

Automatic Riveting Cap-Punching Making Base Crimping Led Bulb Light Manufacturing Machine Assembling Production Line For E27 A60

Tv Smt Ai Production Line Equipment Pcb Led Bulb Light Assembly Full Automatic Smd Smt Line And Machine Manufacture

High speed SMT LED led light assembly production line mounting electronic products machinery pic and place machine

Slim back-lit led panel light making machine assembly production line

China Made Polycarbonate PMMA Pipe Production Line LED Lighting Clear Transparent Acrylic PC Tube Machine PC Tube Extruder

Led Strip Light Silicone Led Strips Flexible Neon Strips Extrusion Machine Production Line

Pc Led Light Tube Making Machine pc Led Light Tube Production Line

Good Sale SMT Pick and Place Machine KAYO-1706 3DSG/KAYO-A6L with 8CCD cameras in LED Lighting Production Line

Plastic PC LED Light Tube Production line / PC modulator tube making extruder machine

Huade Machinery PC Led Light Making Manufacturing Machine production line

PVC Profile Angle Corner Bead Window Frame Door Jamb LED Light Strip Extrusion Production Line manufacturer

LED fluorescent lamp aging line LED production machine LED cast light aging line

PC PVC LED lamp two color round light cover plastic profile extruder production line

PC Lamp Light LED Tube Profile Making Machine PC LED Tube Extrusion Production Line

Siemens Stick Feeder Pick Place Machine for LED Light Production SMT Electronics Production Line

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4