Introduction to Meat Rail Systems

A meat rail system is an integral component in the meat processing industry, designed to streamline the handling and movement of meat products within a facility. This system typically consists of a network of overhead tracks from which meat rail hangers and trolleys can be suspended, allowing for efficient transportation of meat items throughout the processing plant.

Types and Applications

The versatility of meat rail systems is evident in their various types and applications. From meat trolley rail systems that facilitate the easy transfer of large carcasses, to used meat rail systems that offer a cost-effective solution for smaller operations, there is a configuration to suit different operational scales and needs. These systems are commonly employed in slaughterhouses, meat packing plants, and large-scale butcheries to maintain a seamless flow of operations.

Features and Materials

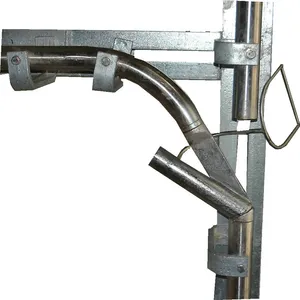

When considering a meat rail system, the focus on features and materials is paramount. Systems are often made from durable materials like stainless steel, which not only supports substantial weight but also ensures ease of cleaning. The inclusion of meat rail switches and meat rail trolleys enhances the functionality of these systems, allowing for directional changes and the smooth handling of meat products.

Advantages of a Meat Rail System

Implementing a meat processing rail system in a facility brings numerous advantages. It optimizes space by utilizing overhead areas for meat transportation, thus freeing up valuable floor space. Moreover, the system contributes to maintaining hygiene standards by minimizing contact with the ground, reducing the risk of contamination. The efficiency of a meat locker rail system also aids in preserving the quality of meat by facilitating quick movement from one stage of processing to another.

Considerations for Selection

Selecting the right meat rail system involves several considerations. The capacity of the system should align with the operational demands of the business. Additionally, the ease of maintenance is crucial; hence, systems with readily available spare parts, such as meat rail trolley components, are preferable. Hygiene is another critical factor, with systems like the butcher meat rail made from easy-to-clean materials being ideal choices.

Enhancing Operations with a Meat Rail Scale

An advanced feature like a butcher rail scale can be integrated into a meat rail system to further enhance operational efficiency. This allows for the weighing of meat products as they are transported, streamlining the process and contributing to precise inventory management. Similarly, a meat hook trolley system can be customized to fit various meat processing tasks, ensuring that the system adds value to the meat handling process.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4