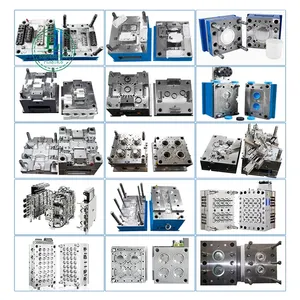

Mold Fundamentals and Applications

Molds are essential tools in the manufacturing sector, serving as the primary method for shaping plastic, metal, and other materials into functional products. They are pivotal in processes like injection molding, where molten material is injected into a mold cavity to solidify into the desired shape. This technique is versatile, catering to the production of intricate components for industries ranging from automotive to consumer electronics.

Types of Molds and Their Construction

The construction of molds varies significantly based on their intended use. Iron molds are common due to their durability and heat resistance, making them suitable for high-volume production runs. Other materials, such as aluminum and steel, are also prevalent in mold making. The choice of material impacts the mold's performance, longevity, and the quality of the final product. For specialized applications, such as bathroom mold removal tools or shoe moulding, the design and material of the mold are tailored to ensure precise outcomes and ease of use.

Features and Advantages of Quality Molds

A well-designed mold can significantly enhance production efficiency. Features like standardized lift bars, connection sizes, and clamp slots can be incorporated to facilitate compatibility across various molding machines. This standardization is crucial for businesses looking to streamline their operations and maintain consistency in product quality. Additionally, the adaptability of molds allows for mold mitigation and mold clean up, ensuring that the production process remains uninterrupted and cost-effective.

Mold Maintenance and Remediation

Maintaining the integrity of a mold is critical for consistent production. Over time, molds can suffer from wear or mold damage, necessitating regular inspections and maintenance. Services such as mold remediation and black mold removal are crucial to extend the life of the mold and ensure the safety of the manufacturing environment. Professionals conducting a mold inspection near me can identify potential issues before they escalate, saving time and resources in the long run.

Choosing the Right Mold for Your Needs

Selecting the appropriate mold requires careful consideration of the design, material, and intended application. Whether it's for creating complex electronic housings or simple bread mold shapes, the precision of the mold directly affects the final product's functionality and appearance. Platforms like Alibaba.com host a multitude of suppliers, offering a diverse array of molds to meet specific manufacturing needs without the constraints of traditional retail models.

Conclusion

In conclusion, molds are indispensable in the production of a vast array of items. By understanding the various types, features, and maintenance requirements, businesses can make informed decisions to optimize their manufacturing processes. Alibaba.com serves as a conduit, connecting buyers with experienced suppliers to fulfill their mold-related requirements efficiently and effectively.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4