Introduction to Monocrystalline Silicon Furnaces

Monocrystalline silicon furnaces are specialized industrial equipment designed for the high-precision melting and processing of silicon, which is critical in the manufacturing of solar cells and semiconductor devices. These furnaces play a pivotal role in ensuring the purity and quality of monocrystalline silicon, which directly impacts the efficiency of the final products.

Types and Applications

The monocrystalline silicon production process utilizes various furnace types, each tailored to specific melting requirements. Applications range from the production of semiconductor-grade silicon for electronics to high-quality substrates for photovoltaic cells. The versatility of these furnaces also allows for their use in research and development settings, where innovation in material science is ongoing.

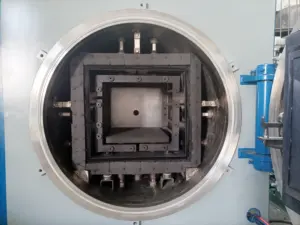

Features and Technical Specifications

A monocrystalline silicon melting furnace is equipped with advanced features to handle the delicate process of silicon production. These include precise temperature controls that can reach up to 2,100 degrees Celsius, ensuring the complete melting of raw silicon. The melting pots within these furnaces can tilt up to 95 degrees for efficient handling of the molten material. Additionally, the integration of a PLC system allows for meticulous operational control, enhancing both safety and efficiency.

Materials and Construction

The construction of a silicon crystal growth furnace involves materials that can withstand extreme temperatures and corrosive environments. The use of insulated large capacitor banks ensures the stabilization of current, which is crucial for maintaining the integrity of the monocrystalline silicon during the melting process. Water-cooling systems are also a standard feature, providing necessary cooling to both the furnace and the molten silicon.

Advantages of Modern Furnaces

Modern silicon processing furnaces boast several advantages, including enhanced melting speeds, which can range from 40 to 60 minutes depending on the metal and machine. The use of electrical induction systems for heating and hydraulic pressure systems for tilting contributes to the overall efficiency and safety of the operation. These advancements ensure that the monocrystalline silicon produced meets the stringent standards required for advanced technological applications.

Choosing the Right Monocrystalline Silicon Furnace

Selecting the appropriate monocrystalline silicon furnace is crucial for businesses aiming to optimize their production of high-grade silicon. Factors such as melting capacity, power input, and operational control systems must be considered to ensure that the equipment aligns with specific production needs. With a diverse range of furnaces available, Alibaba.com serves as a platform where buyers can connect with suppliers to find the equipment that meets their requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4