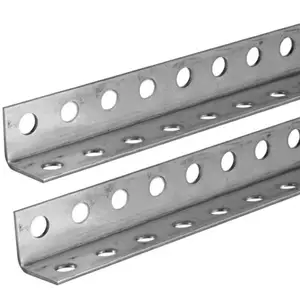

What is Angle Iron With Holes

Angle iron with holes is a versatile, essential component in the construction and fabrication industries. It is a variation of the common angle iron, which is a metal piece that has been bent at a 90-degree angle to form an 'L' shape, with two legs, or flanges, extending outward. The angle iron with holes is specifically designed with perforations in the flanges, providing a more dynamic and flexible range of applications. These holes allow for the attachment of other structural elements using bolts, screws, or welding, enhancing the stability and strength of a structure.

Businesses involved in construction, engineering, manufacturing, and even home improvement can benefit from angle iron with holes as it is a foundational material that supports frameworks, reinforces buildings, and serves as a structural element in various designs. The perforations in the flanges offer an efficient means for fastening or securing the angle iron to surfaces or other materials, which is crucial for ensuring stability and reliability in the final structure.

Angle iron with holes works on the principle of providing a secure and stable support that can bear significant loads while allowing for easy integration with other structural elements. This is achieved through precise manufacturing processes that ensure the holes align with industry standards and the design requirements of the project. The utilization of angle iron with holes can result in cost savings due to reduced need for additional support materials or labor, as well as a reduction in the time required for construction or repairs.

Angle Iron with Holes

Angle iron with holes comes in various configurations to meet different application needs. The type of hole and its pattern can vary, each offering specific benefits:

-

Standard Angle Iron with Round Holes: This is the most commonly used type, featuring regularly spaced round holes along the length of the iron. It's versatile for structural applications and is often seen in the construction industry where it provides rigidity and strength.

-

Slotted Angle Iron: Slotted angle iron includes rows of holes punched with a slot pattern along the length of the material. This design offers more flexibility for attaching bolts and other fasteners, making it ideal for projects that require custom fits or adjustments.

-

Perforated Angle Iron: Similar to slotted angle iron but with a pattern of holes that goes all the way through the material. This type offers enhanced ventilation properties and can often be lighter in weight, making it suitable for use in environments where airflow is important.

-

Galvanized Angle Iron: Treated with a protective zinc coating, galvanized angle iron is resistant to rust and corrosion. It's a long-lasting option that's particularly useful in outdoor or high-moisture settings.

-

Punched Angle Iron with Round Holes: Featuring a series of holes along one or both flanges, this type offers additional structural support and is often used in shelving units and frameworks.

Each type has its common use cases depending on the specific requirements of the project such as load capacity, exposure to elements, and whether a more rigid or flexible structure is needed.

How to choose Angle Iron With Holes

Selecting the right type of angle iron with holes for your business involves considering several factors that align with your specific needs and applications. Here are some key points to keep in mind:

Firstly, consider the material and grade of the angle iron to ensure it meets the strength requirements of your project. The grade of angle iron will determine its resistance to environmental factors and weight-bearing capacity.

Secondly, take into account the type of holes you require. If standard punched holes suit your purpose, ensure they are aligned properly for your intended use. For more intricate or specialized hole patterns, you may need custom solutions that can be provided by certain suppliers.

Additionally, consider the dimensions you need. The size of the angle iron will directly impact how much material you can work with and the structural integrity of your project. Ensure that the dimensions are suitable for your space constraints and that they match your detailed design plans.

Lastly, factor in any additional features that might benefit your operations such as corrosion resistance for outdoor use or fireproofing for high-risk environments. With these considerations in mind and utilizing Alibaba.com's vast selection of options from global suppliers, you can find an angle iron with holes that meets your business's exact requirements.

About Angle Iron With Holes on Alibaba.com

For businesses seeking reliable sources for purchasing angle iron with holes, Alibaba.com stands out as an exceptional global marketplace with an extensive range of options. With suppliers from around the world listing their products on this platform since 1999, buyers can find nearly every conceivable type of angle iron that meets their project specifications — from standard, equal-sized angles for general construction projects to specialized options like perforated or lipped variants for unique applications.

Alibaba.com's platform facilitates seamless communication between buyers and suppliers, ensuring that you can discuss custom requirements such as hole patterns or additional surface treatments with ease. Moreover, with services like Trade Assurance that protect your payments until delivery is confirmed, businesses can purchase with confidence knowing their investments are safeguarded.

The diversity of products on Alibaba.com is matched by a commitment to quality and dependability. Whether you're sourcing angle iron with holes for innovative retail displays or durable supports for industrial machinery, Alibaba.com offers an efficient solution for finding exactly what you need without compromising on service or selection.

Common FAQs for Angle Iron With Holes

What are the primary uses of angle iron with holes?

Angle iron with holes is primarily used to add structural support and rigidity to various construction projects. It's commonly used in framework, braces, reinforcements, shelving units, and other instances where right angles and strength are required.

How does the thickness of angle iron with holes affect its performance?

The thickness of angle iron with holes impacts its strength and load-bearing capacity. Thicker angles can withstand greater loads and provide more support but may not be necessary for lighter applications.

Can angle iron with holes be customized for specific projects?

Yes, suppliers on Alibaba.com offer customization options such as specific hole sizes, hole spacing, and dimensions to meet the unique requirements of a project.

Are there different types of holes on angle iron with holes?

Yes, there are various types of hole configurations available, such as round or square holes, depending on the project's specific needs.

What should I consider when choosing the hole size for my project?

The hole size should be chosen based on the intended application, as larger holes allow for greater airflow while smaller holes provide more support and can prevent the passage of smaller particles.

How do I determine the right length of angle iron with holes for my project?

Measure the area where you will be using the angle iron and factor in any additional length needed for cutting or fitting within the structure.

What is the significance of the angle iron's finish?

The finish of the angle iron, such as galvanization or painting, can enhance its resistance to corrosion and aesthetic appeal. The choice of finish should align with the environmental conditions it will be exposed to.

Is it possible to source angle iron with holes for outdoor use?

Yes, suppliers on Alibaba.com offer angle iron with finishes like galvanization that provide extra protection against outdoor exposure.

How do I know if I need a standard or custom size for my project?

Consider whether standard sizes meet your requirements or if custom dimensions are necessary based on the specific needs of your project.

Can I order a sample of angle iron with holes before making a bulk purchase?

Many suppliers on Alibaba.com provide the option to order a sample of their angle iron with holes so you can assess its quality and suitability for your project before committing to a larger purchase.

What is the difference between hot rolled and cold formed angle iron?

Hot rolled angle iron is formed at high temperatures and is typically less precise but stronger than cold-formed angle iron, which is more economical and suitable for applications that do not require high levels of accuracy.

Are there eco-friendly options available for angle iron with holes?

Suppliers may offer eco-friendly options such as recycled angle iron or suppliers who follow sustainable production practices. It's important to check with individual suppliers about their eco-friendly offerings.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4