A pizza box making machine is a bespoke apparatus crafted to fabricate pizza boxes with efficiency and precision. These contrivances are tailored to the rigors of mass production, guaranteeing that enterprises can furnish their wares with the requisite packaging. The automatic pizza box making machine is distinguished by its capacity to refine the production sequence, ensuring a fluid progression from raw material to end product.

Types of Pizza Box Making Machines

Exploring the spectrum, the pizza box making machine category includes various models, ranging from semi-automatic to fully automatic systems. Each variant presents distinct levels of automation and output. For example, a semi-automatic apparatus may necessitate greater human involvement but is more cost-effective, suitable for smaller ventures. Conversely, a fully automatic system, albeit pricier, can generate a larger quantity of boxes with scant human intervention, fitting for expansive enterprises aiming to amplify their output in response to surging demand.

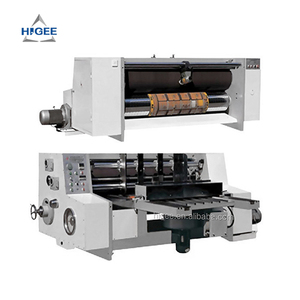

Structure and Operation of Pizza Box Making Machines

The architecture of a pizza box manufacturing machine is a testament to contemporary engineering. Central to its operation is the motor, the dynamo of the entire mechanism. The PLC serves as the cerebrum, facilitating meticulous control and fine-tuning of the production line. Gears and bearings ensure the machine's components move fluidly, while the pump and pressure vessel regulate the adhesive or coating's flow and pressure. Each element is intricately orchestrated to operate in concert, assuring that the end product meets the highest standards of excellence.

Materials Used in Pizza Box Making Machines

The materials chosen for a pizza box maker machine prioritize durability and task appropriateness. Stainless steel is frequently selected for its robustness and corrosion resistance, vital in a machine potentially exposed to adhesive moisture or environmental humidity. Aluminum is employed for its combination of lightness and strength, and premium plastics are utilized for insulation and protective shrouds. These materials guarantee the machine's endurance and sustained performance, offering a sound investment return.

Business Usages and Applications

The pizza box making machine price is vindicated by its broad utility across diverse sectors. Manufacturing facilities benefit from its streamlined box production capabilities, while print shops employ it to tailor packaging with corporate insignias. Food outlets, encompassing pizzerias and snack bars, depend on these machines for essential packaging. In hospitality and advertising firms, the equipment is instrumental in crafting distinctive promotional materials and packaging. The value these machines impart lies in the operational efficiency and customization they afford businesses, enhancing customer service and market differentiation.

Functions of Pizza Box Making Machines

A pizza box manufacturing machine is adept at executing multiple tasks. It slices, creases, and adheres cardboard into the requisite pizza box configuration. Sophisticated models can also imprint and emboss designs, offering an additional dimension of personalization for enterprises seeking to brand their containers. The machine's proficiency in accommodating various cardboard sizes and densities renders it an indispensable asset in the packaging domain.

Features of Pizza Box Making Machines

Salient features of a automatic pizza box making machine encompass its rapid production rate, meticulous cutting and folding, and adjustable operational settings. These attributes distinguish it from its rivals by enabling swift production cycles and the fabrication of an extensive array of box dimensions and styles, catering to a wide customer base.

Benefits of Using Pizza Box Making Machines

The advantages of employing a pizza box maker machine are multifaceted. They offer an economical approach to bulk production, diminish labor expenses, and enhance the uniformity and caliber of the product. For businesses, this equates to augmented productivity, minimized waste, and the capacity to satisfy consumer demands with alacrity.

How to Use and Maintain Pizza Box Making Machines

Effective operation of a pizza box making machine entails configuring the apparatus with precise specifications for the intended box dimensions and motif. Essential maintenance, such as lubrication of moving parts and inspection for wear, is vital for optimal functionality. Regular cleansing is also crucial, particularly to avert the accumulation of adhesives that could disrupt machine performance.

Choosing the Right Pizza Box Making Machine

Identifying the appropriate pizza box manufacturing machine demands a comprehensive evaluation of your enterprise's requirements. Consider the quantity of boxes needed, the diversity of sizes and styles you aim to produce, and the spatial constraints for the machine. The scope of post-sale support, including technical assistance and spare parts availability, should also be factored into your decision.

Installation of Pizza Box Making Machines

Professional installation is imperative for a pizza box maker machine to ensure it is correctly and safely set up. This process may involve assembling various parts, establishing electrical connections, and programming the PLC to align with specific production demands.

Target Audience and Market Needs

The intended market for pizza box making machines comprises entities within the food sector that necessitate dependable packaging solutions, such as pizza parlors, frozen food manufacturers, and snack vendors. These machines are designed to fulfill the requirements of these businesses by supplying sturdy, superior boxes that safeguard their goods and bolster their brand presence.

What are the customization options?

Customization possibilities for a pizza box making machine are extensive, accommodating particular business needs. Options include color selection, PLC brand preference, and compatibility with various raw materials. Companies can adapt the machine to align with their production demands, whether they are processing kraft paper, corrugated board, or alternative substances.

What after-sales services are available?

Post-sale support for a pizza box manufacturing machine is a crucial aspect of the acquisition. Vendors on Alibaba.com extend comprehensive assistance, encompassing online and video technical aid, as well as field maintenance and repair services. This ensures that enterprises can maintain uninterrupted operations with minimal downtime.

How does this machine contribute to business growth?

An pizza box making machine fosters business expansion by facilitating the efficient, high-quality production of pizza boxes. Its high throughput and extended service life render it a cost-effective option for companies seeking to escalate their operations. By guaranteeing a steady supply of pizza boxes, firms can meet customer expectations and broaden their market footprint.

Explore the assortment of pizza box making machines on Alibaba.com, tailored to meet the specific demands of your business and boost your operational efficacy.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4