Introduction to Plastic Water Pump Impellers

Plastic water pump impellers are essential components in various fluid movement applications. These impellers are designed to transfer energy from the motor to the liquid being pumped, creating a flow that facilitates numerous industrial and commercial processes. The versatility of plastic impeller pumps makes them suitable for a wide range of environments, from the pharmaceutical industry to the recreational sector.

Types of Plastic Impellers

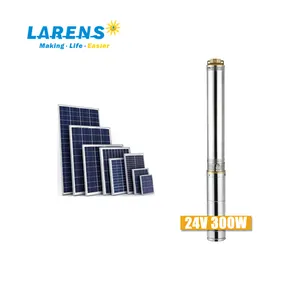

The plastic water pump impeller category encompasses several types, each tailored for specific applications. Centrifugal pump impellers are chosen based on engine power and are commonly used in systems requiring high flow rates. For specialized applications, such as in watercraft like jet skis, jet impellers are preferred for their high-performance capabilities. Additionally, submersible pump plastic impellers offer solutions for underwater applications, highlighting their adaptability to different conditions.

Applications and Features

The application range of plastic pump impellers is extensive. In the pharmaceutical and perfume industries, these impellers are integral to the production process, ensuring the precise and gentle handling of sensitive liquids. The food and beverage sector, including dairy and canning, also relies on these impellers for efficient liquid transfer. For recreational and maintenance purposes, pool impellers are engineered to handle emulsions and small particles, making them ideal for pool cleaning systems.

Material Advantages and Design

Constructed from robust materials, water pump impeller plastic components offer durability and resistance to wear and corrosion. The design of these impellers often includes a dedicated suction hole for efficient liquid intake and an adapter shaft for secure connection to the motor. The axial flow variant is particularly noteworthy for its efficient energy conversion into fluid flow, ensuring effective top-to-bottom circulation.

Choosing the Right Impeller

Selecting the correct plastic impeller is crucial for optimal performance. Factors such as the nature of the liquid, environmental conditions, and the required flow rate play a significant role in determining the most suitable impeller type. Flexible impeller pumps, for instance, are praised for their versatility and can operate under varying conditions, making them a popular choice for diverse applications.

Conclusion

In conclusion, the range of plastic impeller price and specifications available caters to a broad spectrum of needs within the fluid movement industry. While exploring the selection of impellers, it is important to consider the specific requirements of your application to ensure the selection of an appropriate impeller. The plastic water pump impeller serves as a reliable and efficient solution for numerous pumping needs without compromising on performance or durability.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4