Understanding Scarifier Shank

The scarifier shank is a pivotal component in the realm of industrial milling, serving as a crucial tool for surface preparation and material removal. Unlike standard milling bits that are limited to axial cuts, the versatility of a scarifier shank extends to both axial and radial directions, enhancing its functionality in diverse milling operations.

Types and Applications

Scarifier shanks come in various configurations, each tailored to specific industrial needs. The three-axis variant offers flexibility in positioning, suitable for tasks requiring multi-directional cuts, thanks to its vertical and horizontal spindles. In contrast, the four-axis scarifier shank is often employed in the automotive and aviation sectors, where its turnaround table facilitates complex shaping processes. The pinnacle of precision and adaptability is found in the five-axis models, which incorporate three linear and two rotary axes, allowing for intricate customizations.

Features and Materials

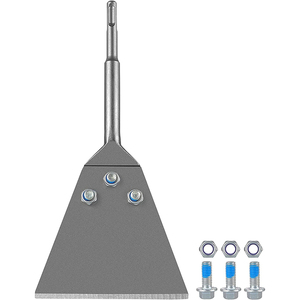

A scarifier shank is distinguished by its robust construction and the materials used, which are selected for endurance and performance under strenuous conditions. The geometry of these tools can range from cylindrical to conical, and even to complex shapes like hemispherical, each designed to meet specific milling requirements. The adaptability of the scarifier shank is further enhanced with the addition of compatible accessories, broadening the scope of its applications without compromising on precision.

Advantages of Scarifier Shank

The scarifier shank offers a multitude of advantages for industrial milling. Its ability to handle both individual pieces and series production makes it an invaluable asset in manufacturing. The design of the scarifier shank allows for efficient material removal, which is essential in shaping mechanical parts to exact specifications. Furthermore, the flexibility in axis configurations ensures that a scarifier shank can be adapted to a wide array of milling machines, enhancing its utility across various industries.

Selection Considerations

When selecting a scarifier shank for industrial milling applications, it is crucial to consider the specific requirements of the task at hand. Factors such as the material to be milled, the complexity of the part design, and the desired finish all play a role in determining the most suitable scarifier shank type. Additionally, the compatibility with existing milling equipment and the potential for accessorizing to expand capabilities should be evaluated to ensure optimal performance and results.

Conclusion

In summary, the scarifier shank is an essential tool for a wide range of milling applications, capable of processing various materials with precision and efficiency. Its design variations cater to different industrial needs, making it a versatile choice for businesses looking to optimize their milling operations. As a component that significantly impacts productivity and quality, the scarifier shank stands as a testament to the advancements in milling technology.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4