Steel ball bearings are small, spherical balls made of steel that are used to reduce friction between moving parts in a variety of machinery and equipment. They are used by mechanics, engineers, and even hobbyists in a wide range of industries, from automotive and aerospace to manufacturing and construction. The history of steel ball bearings dates back to the late 19th century when they were first developed to improve the performance of bicycle wheels. Since then, they have evolved into a vital component in many modern machines and equipment, offering better efficiency, durability, and precision than their earlier counterparts. There are various types of steel ball bearings available for consumer use, including stainless steel and ceramic options, each with its unique properties and advantages. So whether it's a professional in need of high-performance bearings or a DIY enthusiast looking for the right solution, steel ball bearings get the job done.

Advantages of Steel Ball Bearings

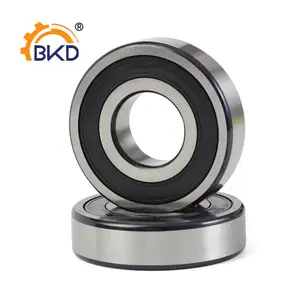

The perks of steel ball bearings extend beyond their compact size and spherical shape. Foremost among these advantages is the impressive durability they offer. Designed for long-lasting performance, these steel orbs can endure extreme temperatures, high-speed rotation, and substantial loads without losing their integrity. When it comes to stainless steel ball bearings, they provide added resistance against corrosion, making them ideal for applications exposed to harsh environmental conditions. Another draw of these steel marvels is their precision. Steel ball bearings deliver smooth motion, ensuring the efficient operation of machinery and equipment. This precision also translates into reduced friction, leading to less wear and tear and, ultimately, longer machinery lifespan. Not to be overlooked is the use of diverse materials in their production. A ceramic ball bearing, for instance, is known for its lightweight nature and excellent thermal properties, allowing ceramic ball bearings to perform exceptionally well in high-speed applications. Lastly, the practical and polished appearance of steel ball bearings adds an aesthetic appeal. The shiny, perfectly round surface not only gives a professional look but also signifies the performance they're known to provide.

Application of Steel Ball Bearings

Steel ball bearings have an expansive range of applications. Industries across the globe rely on the precision and durability of both stainless steel bearing balls and ceramic ball bearings. From advanced engineering to medical and manufacturing sectors, these components find their use. A stainless steel bearing ball, with its superior corrosion resistance, is perfect for applications exposed to harsh environments. Meanwhile, the lightweight and thermal properties of ceramic ball bearings make them suitable for machines that run quickly for extended periods. When it comes to using steel ball bearings, correct operation, selection, cleaning, and maintenance are crucial. Bearings should be chosen based on the specific requirements of the application, including load capacity, speed, and environmental conditions. Cleaning, whenever necessary, should be thorough yet gentle, ensuring the removal of any dust or debris that may affect performance. As for maintenance, regular inspections and lubrication can prolong the lifespan of the bearing and improve its functionality. Installing steel ball bearings is simple but should be performed with utmost care. Improper installation can result in decreased performance and potential damage. A bearing press tool is typically used to ensure correct and safe installation. In closing, the utility of steel ball bearings, whether they are stainless steel or ceramic, is undeniable. Their blend of precision, durability, and versatility continues to drive their widespread use in various applications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4