A sublimation metal blank refers to a specially coated metal surface that is used in the sublimation printing process.

The sublimation process used on sublimation metal plates involves coating aluminum surfaces with a special sublimation layer designed to bond with dye-based sublimation inks. A digital design is created and printed onto sublimation transfer paper, which is then placed on the coated metal. The layers are subjected to heat and pressure using a heat press, causing the inks to sublimate into a gas that is absorbed by the coating. Upon cooling, the sublimated inks solidify, creating a vibrant and durable full-color image embedded into the metal. The process is commonly used in the production of personalized and customized items. The durability and scratch resistance of sublimation prints on metal makes them suitable for various applications. Better quality of metal blanks ensures proper adhesion and longevity of the printed image. The coatings are specifically engineered to receive and retain the sublimated inks, resulting in sharp, detailed, and scratch-resistant prints on the metal surface. Overall, the combination of metal and specialized coatings makes sublimation metal blanks a popular choice for personalized and customized items in the sublimation printing industry.

Materials used as sublimation metal blanks

Sublimation metal blanks, versatile materials widely employed for sublimation printing applications, are crafted from a range of metals. However, they are typically made of aluminum due to its favorable properties for the sublimation process. Aluminum blanks for sublimation or aluminum sublimation blanks feature a smooth surface coated with a specialized sublimation layer. This coating, which plays a pivotal role in the process, is typically a polymer designed to absorb and bond with sublimation inks, ensuring the creation of vibrant and enduring prints. The aluminum sheets used for sublimation metal blanks come in various thicknesses, typically ranging from 0.020 inches (20 mil) to 0.125 inches (125 mil). Thicker blanks may be used for applications where additional durability or a more substantial feel is desired.

Applications for sublimation metal blanks

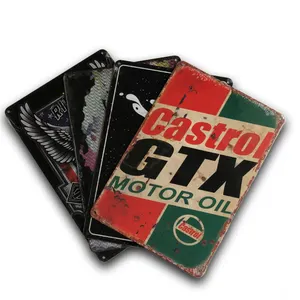

Sublimation metal blanks are at the forefront of personalized and durable product customization. This versatile method of sublimation printing finds its way into various industries, from photography to signage. The appeal of sublimation on metal extends to the production of unique items such as aluminum sublimation keychain blanks, aluminum sublimation ornament blanks, nameplates, and license plates. The process allows for the reproduction of intricate details, gradients, and a spectrum of colors, creating a premium aesthetic that stands out in the market. Additionally, sublimation tins offer another avenue for creativity. These tins, when subjected to the sublimation process, become canvases for unique designs. They are perfect for creating personalized and visually striking items, whether it be for promotional products or special gifts. Whether it's the allure of blank sublimation metal signs, the elegance of sublimation metal photo blanks, or the versatility of round metal sublimation blanks, the sublimation process on metal continues to leave a lasting impression on various industries.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4