A valve grinding machine is a crucial process in maintaining the performance and longevity of engines. Good valve grinding equipment is essential to achieve better results.

What is a valve grinding machine?

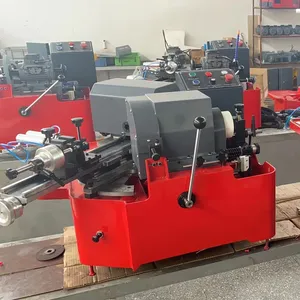

Valve grinding equipment is a specialized tool used in the automotive and engineering industries to restore and maintain the performance of engine valves. These machines are designed to grind and shape the surfaces of engine valves, ensuring proper valve seating and sealing for better engine performance. The valve grinder uses abrasive wheels or stones to remove material from the valve face and valve seat. The grinding head of the machine, often equipped with adjustable grinding angles, is used to grind the valve face, while a separate grinding stone or tool is used to grind the valve seat. This grinding process ensures that the valve and valve seat form a seal, preventing leakage and increasing engine efficiency. Several valve grinding machines are available, each designed for specific applications and engine types. Automotive valve grinder is commonly used for grinding valves in automotive engines, while cylinder head valve grinders are specifically designed for grinding valves in cylinder heads. A valve seat grinder grinds valve seats to ensure proper seating and sealing. For smaller engines, there is the compact and portable small engine valve grinder available. Additionally, a centerless valve grinder is a specialized machine that provides high-precision valve grinding without the need for centering mechanisms.

Advantages of a valve grinding machine

Firstly, properly ground valves optimize engine performance by maintaining a tight seal and efficient combustion. This leads to smoother operation, increased power, and better fuel efficiency. Secondly, valve grinding machines help extend the lifespan of valves. Regular grinding removes deposits and wear on the valve surfaces, preventing premature wear and damage. This prolongs the lifespan of the valves, reducing the need for frequent replacements and saving on costs. Thirdly, valve grinding machines contribute to reduced emissions. Proper valve seating and sealing reduce valve leakage, which can result in exhaust gas leakage and increased emissions. These machines help reduce emissions and environmental impact by ensuring a tight seal. Furthermore, investing in valve grinding machines can lead to cost savings. By restoring and maintaining the performance of engine valves, these machines help avoid costly engine repairs or replacements. Regular valve grinding prevents valve-related issues that can lead to more significant engine problems, saving both time and money in the long run.

Choose the suitable valve grinding machine for specific needs and experience improved engine performance and reliability.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4