Types of Bus Fan

Bus fans are specialized electric fans designed for cooling and ventilating buses. They play a crucial role in maintaining comfortable passenger environments, especially during hot weather, while also protecting vital bus components from overheating.

Why Bus Fans Matter: Proper ventilation and cooling not only enhance passenger comfort but also extend the lifespan of critical bus components and improve overall vehicle efficiency.

Bus-Mounted Fan

Mounted directly on the bus body or engine compartment, these fans provide essential ventilation and cooling. They primarily help maintain optimal engine temperature, improving performance and longevity.

Applications: Engine cooling, general ventilation

Types: Available in axial and centrifugal configurations

Bus Radiator Fan

Connected directly to the radiator system, these fans are critical for maintaining proper coolant temperature. They're especially important during idling or low-speed operation when natural airflow is insufficient.

Best for: Temperature regulation during low-speed driving or stationary idling

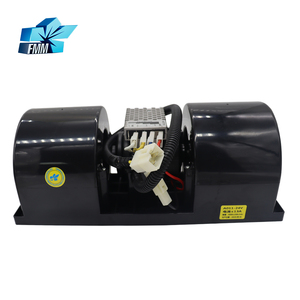

Air Conditioning (AC) Fan

These fans circulate air through the bus's evaporator coils, ensuring comfortable interior temperatures. They're the primary component for passenger comfort in hot weather conditions.

Feature: Often includes multiple speed settings for customized cooling

Electric Cooling Fan

Powered by the bus's electrical system, these versatile fans can serve multiple cooling applications throughout the vehicle, including engine cooling, air conditioning, and battery temperature regulation.

Advantage: Improves bus performance and extends component life

Cross-Flow Fan

A specialized centrifugal fan design that moves air perpendicular to the rotor axis. This unique configuration allows for targeted, directed cooling of specific bus components.

Best for: Components requiring precise, direct cooling

Shrouded Fan

Features a protective housing or frame surrounding the fan blades, which both directs airflow and increases efficiency. The shroud design also enhances safety by preventing contact with moving blades.

Advantage: Improved airflow efficiency and enhanced safety

| Fan Type | Primary Function | Best Application | Key Advantage |

|---|---|---|---|

| Bus-Mounted Fan | Engine cooling and ventilation | General bus operation | Versatile mounting options |

| Bus Radiator Fan | Coolant temperature regulation | Low-speed or idling operation | Prevents engine overheating |

| AC Fan | Interior comfort cooling | Passenger area temperature control | Customizable cooling intensity |

| Electric Cooling Fan | Multi-purpose cooling | Various cooling needs throughout bus | Versatility and electrical efficiency |

| Cross-Flow Fan | Targeted component cooling | Specific components requiring direct airflow | Precise cooling direction |

| Shrouded Fan | Enhanced airflow direction | Applications requiring efficiency and safety | Improved airflow and protection |

Specifications and Maintenance of Bus Fans

Air Bus Fan Specifications

Size and Airflow Capacity

Air bus fans come in various sizes to fit interior bus spaces, with airflow capacities ranging from 500 to 2000 CFM (cubic feet per minute) or equivalent L/s (liters per second) measurements. The appropriate capacity depends on bus size and passenger density.

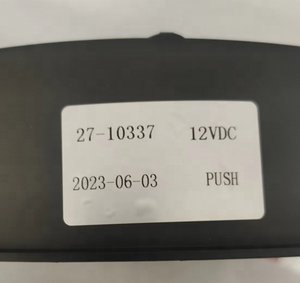

Power Consumption

Energy efficiency is critical, especially for electric and hybrid buses. Manufacturers provide specific wattage ratings and may feature energy-saving technologies like variable speed control and low-power motors.

Noise Level

Passenger comfort demands quiet operation. Bus fans typically include noise level specifications in decibels (dB) and may incorporate noise-reduction technologies to minimize disruption.

Control Options

Most air bus fans integrate with the vehicle's climate control system. Options range from manual controls to programmable systems that automatically adjust based on temperature or humidity conditions.

Air Filtration

Many bus fans incorporate filtration systems to improve air quality. Specifications typically detail filter type (HEPA, washable, etc.) and recommended replacement/cleaning intervals.

Construction Material

Bus fans utilize durable, corrosion-resistant materials such as aluminum, stainless steel, or high-strength plastics designed to withstand vibration and varying environmental conditions.

Mounting Options

Installation specifications include mounting method (surface, recessed, bracket) and positioning options (ceiling, wall, window) to accommodate different bus designs.

Maintenance Requirements

| Maintenance Task | Frequency | Purpose | Procedure |

|---|---|---|---|

| Regular Cleaning | Monthly | Ensure optimal airflow and prevent noise | Use soft brushes, vacuum cleaners, or mild detergents to remove accumulated dust and debris |

| Air Filter Replacement | Per manufacturer specs (typically 3-6 months) | Maintain air quality and proper airflow | Inspect, clean, or replace filters according to manufacturer guidelines |

| Lubrication | Semi-annually | Reduce friction, noise, and extend lifespan | Apply recommended lubricant to motors and bearings at specified points |

| Electrical Connection Inspection | Quarterly | Prevent performance issues and electrical hazards | Check for damage, corrosion, or loose connections; repair as needed |

| Motor and Bearing Inspection | Annually | Identify early signs of wear or damage | Check for unusual noise, vibration, or heat; replace damaged components |

| Control System Check | Quarterly | Ensure proper operation and response | Test speed settings, direction control, and other functions |

| Structural Integrity Check | Semi-annually | Maintain stability and safety | Inspect housing, brackets, and mounts for damage; tighten fasteners |

Important: Always disconnect power before performing maintenance on bus fans to prevent injury. For complex repairs, consult with a qualified technician or refer to the manufacturer's service manual.

How to Choose the Right Bus Fan

Selecting the optimal bus fan is crucial for effective ventilation, passenger comfort, and operational efficiency. Consider these key factors to make an informed decision:

Size and Bus Type

Match fan power and dimensions to your specific bus size. Larger vehicles require more powerful fans with higher airflow capacity, while smaller buses need appropriately scaled solutions.

Tip: Measure interior space carefully before selecting fan dimensions

Noise Level

Passenger comfort depends significantly on quiet operation. Look for fans with noise-dampening technology and check decibel (dB) ratings – lower numbers indicate quieter operation.

Recommended: Under 50dB for optimal passenger comfort

Power Consumption

Energy-efficient fans reduce strain on the bus's electrical system and lower operational costs. Consider models with variable speed settings that allow for power optimization based on actual cooling needs.

Look for: Energy Star ratings or efficiency certifications

Fan Placement

Strategic positioning ensures even airflow throughout the bus. Analyze your bus layout to identify optimal mounting locations that eliminate hot spots and provide comprehensive ventilation.

Consider: Multiple smaller fans instead of fewer large ones for better distribution

Durability

Bus environments involve constant vibration and temperature fluctuations. Select fans constructed from high-quality, corrosion-resistant materials with robust mounting systems that can withstand these challenging conditions.

Recommended: Stainless steel or reinforced polymer construction

Installation Ease

Look for fan systems that include comprehensive installation instructions, necessary hardware, and straightforward mounting options to minimize downtime and installation costs.

Feature: Plug-and-play connectivity with existing systems

Airflow Capacity

Measured in CFM (cubic feet per minute), this rating indicates how effectively a fan moves air. Calculate your required airflow based on bus volume and desired air exchange rate.

General guideline: 15-25 CFM per passenger for adequate ventilation

Control Options

Modern bus fans offer various control mechanisms from simple manual switches to integration with centralized climate systems. Select options that provide appropriate control for your operation type.

Advanced feature: Zoned climate control for different bus sections

Safety Features

Prioritize models with comprehensive safety features like blade guards, thermal protection, and safe mounting systems to protect passengers and prevent mechanical failures.

Must-have: Overload protection to prevent electrical issues

Expert Recommendation: Instead of focusing solely on initial purchase cost, calculate the total cost of ownership including energy consumption, maintenance requirements, and expected lifespan. Higher-quality fans often provide better value over their operational lifetime despite higher upfront costs.

DIY Bus Fan Replacement Guide

Replacing a bus radiator fan requires careful attention to detail as it's connected to the vehicle's critical heating system. Follow this step-by-step guide for a successful replacement:

Essential Tools and Materials

Safety Warning: Always ensure the bus engine is completely cool before beginning work to avoid burns from hot components or coolant. Wear appropriate safety gear throughout the process.

Step-by-Step Replacement Process

-

Prepare the Bus

Turn off the bus engine and open the hood to access the fan assembly. Allow sufficient time for all components to cool completely before proceeding.

-

Disconnect the Battery

Locate the bus battery and disconnect the negative terminal first, followed by the positive terminal. This prevents electrical shorts during the replacement process.

-

Drain the Cooling System

Position a drain pan beneath the radiator drain valve. Open the valve and allow the coolant to drain completely. Properly dispose of used coolant according to local regulations.

-

Disconnect Heating System

Carefully remove the hoses connecting to the heating system. Use clamps or plugs to prevent remaining coolant from leaking onto other components.

-

Remove the Old Fan Assembly

Use the appropriate wrenches and screwdrivers to unfasten mounting bolts and brackets securing the fan assembly. Note the positioning and connection points for reinstallation.

-

Install the New Fan Assembly

Position the new fan assembly in the same orientation as the old one. Secure all mounting brackets and bolts to the manufacturer's torque specifications.

-

Reconnect the Heating System

Reattach all hoses to their proper connection points on the heating system. Ensure all connections are tight and secure to prevent leaks.

-

Refill the Cooling System

Add the appropriate type and amount of coolant to the system as specified in the bus's service manual. Check for proper fluid levels.

-

Reconnect the Battery

Reconnect the battery terminals in reverse order: positive terminal first, followed by the negative terminal.

-

Test the System

Start the bus and allow it to run until it reaches normal operating temperature. Check for proper fan operation and inspect for any coolant leaks that may require attention.

Professional Tip: Take photos of the original installation before disassembly to serve as a reference during reassembly. This can be particularly helpful when dealing with complex wiring or hose connections.

Frequently Asked Questions

A bus fan serves multiple critical functions in commercial buses and coaches. Primarily, it creates and maintains proper airflow throughout the vehicle, which helps regulate temperature for passenger comfort, especially during hot weather. Additionally, bus fans assist in ventilating the interior space, removing stale air and preventing condensation buildup on windows. From a mechanical perspective, certain bus fans play vital roles in cooling engine components and preventing overheating of critical systems.

Bus fans operate on basic principles of air displacement. Electric motors drive fan blades that create pressure differentials, forcing air to move from high-pressure to low-pressure areas. Depending on the specific type and application, bus fans may:

- Use axial designs that push air parallel to the fan's axis (like traditional ceiling fans)

- Employ centrifugal designs that move air perpendicular to the intake (common in HVAC systems)

- Utilize cross-flow configurations for specialized applications

The fan's motor receives power from the bus's electrical system, with controls allowing for variable speeds and directional adjustments. Modern bus fans often integrate with computerized climate control systems that automatically adjust fan operation based on temperature sensors, humidity readings, and passenger comfort settings.

Bus fans should be inspected during regular maintenance intervals, typically every 3-6 months for commercial vehicles. Key maintenance indicators include:

- Unusual noise or vibration during operation

- Decreased airflow performance

- Motor overheating or unusual odors

- Visual damage to blades, shrouds, or mounting systems

With proper maintenance, most quality bus fans will last 3-5 years before requiring replacement. However, this timeframe can vary significantly based on operating conditions, usage frequency, and maintenance practices. Preventative maintenance, including regular cleaning and lubrication, can substantially extend fan lifespan.

Yes, bus ventilation systems can often be upgraded for improved performance. Popular upgrades include:

- Installing higher-capacity fans with greater CFM ratings

- Upgrading to energy-efficient models with variable speed controls

- Adding supplementary fans for targeted cooling in problem areas

- Implementing smart controllers that optimize fan operation based on real-time conditions

- Integrating air filtration systems for improved air quality

Before upgrading, consult with a professional to ensure compatibility with your bus's electrical system and to verify that structural modifications (if needed) won't compromise vehicle integrity or safety.

Bus ventilation systems may use either AC (alternating current) or DC (direct current) powered fans, each with distinct characteristics:

AC Fans:

- Typically run directly from the vehicle's alternator or external power source

- Generally more powerful and suitable for large-scale ventilation

- Often less energy-efficient than DC equivalents

- Usually simpler in design with fewer electronic components

DC Fans:

- Run from the bus's 12V or 24V electrical system

- More energy-efficient, drawing less power

- Typically offer better speed control options

- Often quieter operation due to electronic commutation

- Generally preferred in modern bus designs, especially in battery-electric vehicles

The selection between AC and DC depends on the specific application, available power systems, and performance requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4