(977 products available)

Machines for polishing optical fibers fall into four main categories. These categories are based on the fiber type to be polished and the polishing method.

A manual polishing machine is perhaps the simplest type of polishing equipment. It usually contains a flat, polished, stone-held wooden board. The board is curved, allowing the user to smoothly move a fiber over it. The worker must fully understand the board tension, fiber speeds, and polishing film grades' use.

This machine has no power, but the manual work means the results depend on the master's skills. The artisan can alter the pressure, angle, and rotation on the optic fiber for more control.

Usage benefits:

Disadvantages:

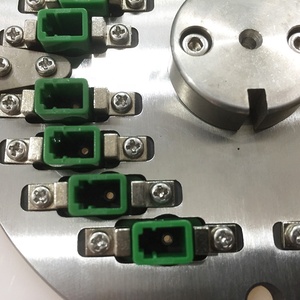

Most of the work is still physical with a series of semiautomatic steps. A fiber is placed in a fixture, and a motorized plate moves a polishing disk over the fiber. It needs some input from the artisan but less than fully manual tools.

The main edge over purely manual tools is the faster and more standard output of the machine components.

Benefits:

Disadvantages:

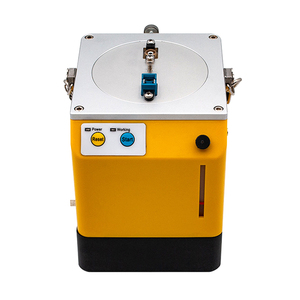

A fully automatic fiber polishing machine is suitable for mass production. The machine has robotic parts that position and polish the fibers without human influence. While this machine is large and expensive, it is smooth and fast.

Production machines are made to do major production runs with consistent outputs. These machines apply standard polishing pressure and speed to ensure all fibers are the same.

Benefits:

Disadvantages:

Therefore, the fiber polishing machine role in many industries is vital in telecommunications.

In telecommunications, optical fibers are used for high-speed internet and communication networks. They, therefore, need precise polishing for better fiber performance and signal transfer. Polishing machines ensure only low levels of light loss occur during transmission. It leads to clearer, cleaner signals over long-distance transmission. This reduces the energy needed for signal boosting, resulting in cost savings.

For the medical industry, fiber optics enable minimally invasive imaging and laser surgeries. In surgical tools, polished fibers offer high accuracy and control in procedures. Polishing machines improve safety and recovery time. It influences demand in the medical field in laser surgery and diagnostics.

The defense and aerospace sectors also rely on fiber optics for secure communication and imaging systems. Thus, resistance to harsh conditions and high performance are requirements in this field. Polished fibers have lower signal loss and better durability under extreme conditions. This enhances the optical fiber painting machine's role in ensuring system reliability and security.

Lastly, in industrial automation, fiber optics are used in sensors and robotic vision systems. This leads to faster data transmission and improved system efficiency. Polishing machines enhance sensor accuracy and lead to better system performance. It conforms to the growing demand for automation in diverse industries like manufacturing and logistics.

The fiber is first prepared by removing any old coatings through mechanical stripping. The stripped portion is then polished using a polishing jig. Here, the fiber is held in a controlled environment while it is rubbed against a polishing pad or disk. This disk contains a special polishing film or abrasive that smooths the fiber end. It occurs while maintaining the important radius of the fiber core. The polishing process then finishes the fiber ends to a mirror-like smoothness. After polishing, the fiber ends are cleaned to remove any polishing debris or particles stuck to it. The final step is to examine the polished ends through a microscope or other devices.

Optical fibers are sensitive materials. They need proper polishing for high performance in their varied applications. Improper polishing introduces surface or micro-bending losses. It affects the fiber's long-term reliability. The optical fiber polishing machine must maintain stringent quality controls to evade these effects.

Polishing speed control needs to be accurate. Excessive speeds increase fiber heat and risk causing thermal damage. Slower speeds risk prolonging operation and causing inconsistent results. Thus, all machines must have reliable speed settings.

Standardization of polishing techniques is also necessary. Inconsistent methods cause variations in fiber end finishes. They affect connection quality and overall system performance.

Thirdly, it ensures that the polishing materials used are of high quality. OEM films should have uniform grit sizes to allow even abrasion across the fiber surface. Using improved materials evades scratches on the fiber ends. Such scratches lead to increases in signal loss.

It is also important to monitor the working environment in terms of cleanliness. Dust, dirt, and other debris interfere with the polishing process. They lead to contamination on the fiber ends. Proper cleaning and maintenance of machines help alleviate this risk.

Finally, it ensures operator safety. Optical fibers break and create sharp splinters. These splinters injure the hands, causing cuts and wounds. Wearing special polishing pads prevents this from happening. Focusing on good ergonomics on the machine limits fatigue and boosts comfort. This helps prevent accidents when operating the machines. Eye protection is also vital to avoid splinter injury in the eyes.

Adhering to these quality and safety measures ensures consistent performance from optical fiber polishing machines while maintaining the safety of those operating them.

A1. It is for attributing optical components to the required quality. Polishing pads smoothly move over the optical surface to remove material and leave a smooth finish.

A2. Factors such as polishing time, pad hardness, fiber material, and polishing slurry type impact the output of the optical fiber polishing machine.

A3. Polishing films should be checked for wear after about 30 fibers have been polished. If films show signs of wear or tearing, replace them immediately for best results.

A4. No, it does not consume a lot of power. The machine's energy consumption level depends on various factors, including its type and intensity.

A5. Cleaning fibers after polishing removes any debris or residue left from the polishing process. It is very vital to prevent signal loss or damage to components during fiber installation.

A6. Fiber polishing can be both wet and dry. Wet polishing uses a slurry to reduce heat and friction, while dry polishing does not use lubrication.