All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(3054 products available)

Paper chipboard sheets are thick, grey cardboard used in packaging and crafting products. It is made from recycled paper, which makes it a more sustainable option for businesses. Paper chipboard sheets are versatile and have a range of applications, such as:

The paper chipboard sheets are categorized into grades A, B, C, D, and E, which are further subdivided into backings and bristols.

Paper chipboard sheets also come in different finishes, including:

Paper chipboard sheets are versatile and have multiple applications. These applications take advantage of their features and functions, which include:

Structural support

Chipboard paper sheets are used in the packaging industry to make boxes and inserts. They provide sturdy and durable packaging for products. Chipboard is also used to manufacture book covers, report covers, and portfolio covers. They offer a solid and protective backing for notebooks, notepads, and writing pads. The structural stability of the paper chipboard sheets helps to protect the contents from bending and creasing. They are also used to make greeting cards and invitations that give an important and festive feel.

Customization and design

These paper boards come in different thicknesses, sizes, and colors. This allows customization and designing of different products. The printable surface of the paper chipboard allows it to be printed on and designed. This feature makes promotional products like custom coasters and photo frames. The rigidity and thickness of the chipboard paper give the product durability and a high-quality feel. Paper chipboard is also used to make puzzles and games. It is printed on and cut into various shapes and designs.

Eco-friendly

These products are made from recycled paper products. This reduces waste by utilizing it. Paper chipboard sheets are recyclable. This makes them a good option for manufacturers and consumers who want to reduce their carbon footprint. They are also biodegradable. These papers offer a sustainable option for product manufacturing and are environmentally friendly.

Cost-effective

Paper chipboard is an inexpensive material. This makes it a good option for the production of items that need to be produced in large quantities. It is a good option for projects and products that are budget-friendly. The low cost of these products does not compromise their quality. They are versatile and provide structural integrity to the manufactured products.

Versatility

These products can be used in different industries. They are used in the arts and crafts industry to make customized products. Paper chipboard is also used in the construction industry to make temporary barriers and signs. It is an invaluable product that can be used in the office for organizational tasks and also at home for DIY projects.

Paper chipboard sheets are widely used in different industries to provide support and protection to products. Some of the industries that use chipboard products include:

Wholesale buyers should consider the following factors when buying chipboard paper for resale.

Paperboard Chipboard Sheet Purpose

The first thing to consider is the intended use of the chipboard. Different applications require different types of chipboard with varying thicknesses and strength. For instance, construction projects require a heavy-duty backing chipboard paper, while arts and crafts projects can work with a light to medium chipboard paper. Knowing the intended use helps in selecting the right grade and thickness of the chipboard, which ensures customer satisfaction.

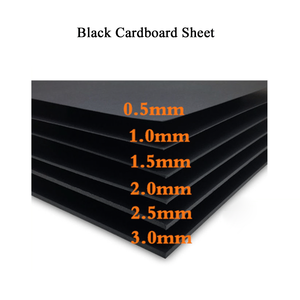

Paperboard Chipboard Sheet Thickness and Weight

Another important factor is the thickness and weight of the sheets. The thickness determines the durability and strength of the sheets, while the weight affects handling and transport. The two factors should be balanced to ensure the selected product meets the customers' demands. In addition, the chipboard's weight and thickness affect the shipping costs, which in turn affects the profits of the buyer. Therefore, it is important to pay attention to these two factors.

Paperboard Chipboard Sheet Quality

It goes without saying that the quality of the product has to be top-notch. This ensures the buyers' customers are satisfied and return for more. The quality of the chipboard is indicated by the smoothness and cleanliness of the surface. There should be no visible contaminants or debris. In addition, there should be no major warping or bending. The sheets should be straight and have uniform thickness. Lastly, the edges should be clean and not frayed.

Paperboard Chipboard Sheet Environmental Consideration

Sustainability is a big deal in the modern world. Therefore, business owners have to consider it when buying products. A good place to find eco-friendly products is the product description section. The information is often detailed and clear, allowing buyers to know what they are getting.

Q1: What are the standard sizes of paper chipboard sheets?

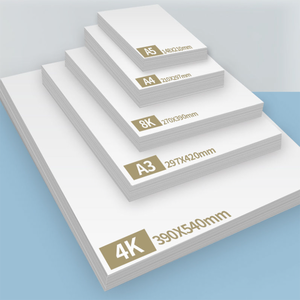

A1: The most common dimensions are 20 x 30 inches and 22 x 28 inches. These sizes are frequently used in printing and crafting projects. However, these sheets are also available in custom sizes to meet specific project requirements.

Q2: Can chipboard be recycled?

A2: Yes, chipboard can be recycled. It is generally considered less harmful than other cardboard products because it is not coated with plastic or wax. However, the recycling process may vary depending on local facilities and the chipboard's contamination level.

Q3: What type of paper is chipboard made of?

A3: Chipboard is made from recycled paper. It consists of leftover paper scraps from the manufacturing process mixed with water and glue. This mixture is pressed into sheets and dried to form chipboard.