(14825 products available)

Perforated aluminum wall panels are aluminum sheets with holes or decorative patterns. These panels are lightweight and excellent for use in different applications. They are used in architectural applications, automotive parts, electronic casings, etc.

Perforated aluminum panels are preferred because of their ability to resist corrosion. They are also preferred because they can be customized to fit different needs and applications. The word perforated means that the aluminum panels have holes or openings in them. These holes or openings can be arranged in different patterns. The size and shape of the holes can also differ. The purpose of these holes is to allow light to pass through. They also allow air to circulate and reduce the weight of the panel.

Perforated aluminum panels come in different types. Each type is tailored for specific needs and applications. Here are some of the types of perforated aluminum panels:

Perforated aluminum panels are increasingly being used in building construction due to their many useful features. As such, they are a popular choice for architects and builders when designing and constructing modern buildings. Their applications are also widespread across various industries. Here are some of their features and functions:

Lightweight yet Durable

The perforated aluminum wall panel is made of aluminum, which is lightweight. This makes them easy to handle and transport, which in turn reduces construction costs. It is also strong but lightweight. Aluminum is known for its strength and lightweight properties. These panels can be used in a wide range of applications without being damaged.

Versatile and Aesthetic Design

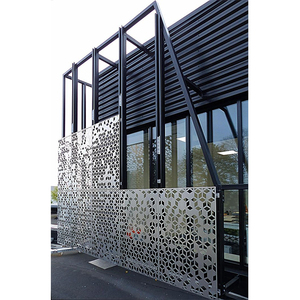

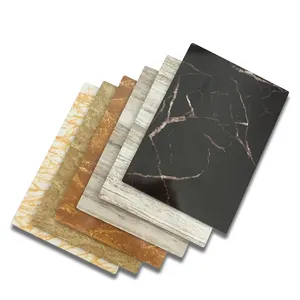

Perforated wall panels come in different shapes, sizes, and hole patterns. This allows architects and designers to be creative when designing buildings. The panels also have different finishes, such as powder coating, anodizing, and natural aluminum. This improves the visual appearance of buildings. They improve the visual appearance of buildings by providing a sleek, modern look.

Customizable

These panels can also be customized to meet specific requirements. This includes adjusting the size, shape, and perforation pattern of the panels. Customization improves the functionality of the panels. For example, panels can be designed to provide more light or privacy. They can also be tailored to meet the acoustic needs of a particular building.

Ventilation and Natural Light

The holes in the perforated aluminum panels allow for air to circulate and pass through. This improves airflow and reduces the heat that is trapped in buildings. Perforated panels also allow natural light to enter through the holes. This reduces the need for artificial light during the day. The circulation of air reduces the need for artificial cooling in buildings.

Noise Reduction

Some perforated panels are filled with acoustic material. For example, fiberglass. This is important because it reduces the amount of noise that passes through the panels. The panels also have a textured surface. This helps to reduce sound waves by absorption.

Eco-Friendly

Perforated wall panels are made of aluminum. This metal can be recycled many times without losing its quality. As such, aluminum panels can be recycled at the end of their life span. Using aluminum panels reduces the amount of waste that is put in landfills. It also conserves the natural resources that are used to mine and produce aluminum.

Perforated wall panels have different applications in various industries. They provide functional, aesthetic, and environmental benefits. Here are some common usage scenarios:

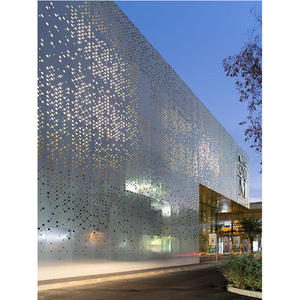

Architectural Design

Perforated aluminum wall panels are important in modern architecture. They provide both practical and aesthetic functions. These panels can be used for building facades. They not only improve the visual appeal of a building but also offer essential functions such as energy efficiency and environmental sustainability. These panels are also used for interior wall cladding. This ensures that these spaces have a contemporary feel and are also functional.

Transportation Hubs

Perforated aluminum panels are used in airports, train stations, and bus terminals. They create a visually appealing and comfortable environment for travelers. They are also used in high-traffic areas such as platforms and baggage claim areas. This is due to their ability to withstand wear and tear. In addition to that, they can be easily cleaned.

Commercial Spaces

These panels are used in office buildings, shopping malls, and hotels. They create a sophisticated and modern atmosphere. For instance, in office building lobbies, these panels come in different designs, creating a welcoming first impression. They are also used in ceiling and wall cladding in hotels and shopping malls. This adds to the spaces' visual appeal and improves their acoustic properties.

Public Areas

Perforated aluminum panels are used in museums, galleries, stadia, and convention centers. They improve the aesthetic and functional properties of these spaces. For instance, in museums and galleries, these panels improve the lighting by filtering and diffusing natural light. This helps to create a dramatic effect on the displayed art pieces.

Healthcare Facilities

Perforated aluminum panels are used in hospitals, clinics, and healthcare centers. They create clean, contemporary, and sterile environments. These panels are easy to clean and maintain. They also have antimicrobial coatings which help to inhibit the spread of germs and bacteria.

Educational Institutions

These panels are used in schools, colleges, and universities. They create functional and appealing learning environments. For instance, they can be used in lecture halls and classrooms. They provide sound control and improve acoustics. They can also be used in outdoor spaces such as amphitheaters and courtyards. This adds to the visual appeal of the space.

Industrial Applications

Perforated aluminum panels are used in factories, warehouses, and manufacturing plants. They create efficient and practical environments. For instance, these panels can be used for machinery housing. They allow for ventilation and airflow, thus preventing overheating of the machines. At the same time, they provide protection by preventing debris from entering the machinery.

Perforated aluminum panels are an attractive addition to any building project, but before purchasing, it is important to consider a few things to ensure the product meets the required specifications.

Purpose

Identifying the purpose for which the perforated panel will be used is important. Will it be used for decorative purposes, to allow air and light to pass through, or to reduce sound? Knowing the intended purpose will guide the decision-making process when choosing the right panel.

Hole pattern and size

The type of holes and their size will affect the visual appeal and functionality of the panel. It's important to choose a style that matches the architectural design of the building. Most manufacturers provide samples of the different hole patterns, and sizes which can be used to determine the best fit for a project.

Panel finish

Perforated aluminum wall panels come in different finishes, like wood, powder coating, and anodized finishes. The finishes not only enhance the appearance but also offer protection from weather elements. Consider the climate and the type of finish that will best suit the project's needs.

Sound insulation

Perforated panels can help reduce noise levels, especially in urban areas. If sound insulation is important, choose panels designed specifically for that purpose. These panels have a sound-absorbing material placed at the back.

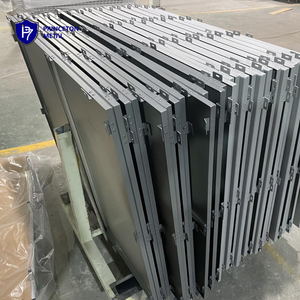

Panel thickness

The thickness of the perforated aluminum panels affects durability and cost. Thicker panels are more durable but cost more than the thinner ones. Consider the budget and the required durability when choosing the thickness.

Panel size

Perforated panels come in different sizes. When purchasing, make sure the size can be fitted to the intended space. Also, consider the number of panels required and the cost per panel.

Quality

Always choose high-quality perforated aluminum panels from reputable manufacturers. Check the reviews and testimonials of previous clients to gauge the quality of their work. It is also important to consider their customer service and the time they will take to deliver the panels.

Q: How are the holes cut in the aluminum panels?

A: There are a few ways to create the holes in the aluminum panels. The choice depends on the intended use of the panels and the needs of the buyer. Some common options include laser cutting, CNC punching, and stamping.

Q: What is the lifespan of aluminum panels before they need to be replaced?

A: Aluminum panels can last for a long time, depending on the environment in which they are installed and how well they are maintained. They are generally very durable and can last anywhere from 10 to 30 years or even longer. However, factors like extreme weather conditions, corrosive environments, and inadequate maintenance can shorten their lifespan.

Q: Are aluminum panels easy to install?

A: Aluminum panels are generally very easy to install because they are very lightweight. This makes it simple to attach them to most surfaces. Aluminum panels are also very versatile and can be installed using various methods, such as welding, riveting, or bolting.

Q: Are perforated panels sound-proof?

A: No, aluminum panels are not sound-proof. The holes in the panels allow sound to pass through. However, some panels are specially designed to reduce or minimize the transmission of sound. These panels have smaller, closely spaced holes or are made with thicker gauge aluminum.