Understanding Wire Mills

Wire mills are specialized industrial equipment used in the production of wire, a fundamental component in numerous applications. These mills are designed to transform metal into wire by passing it through a series of processes that gradually reduce its diameter to the desired size. The versatility of wire mills allows them to work with various metals, including steel, aluminum, and copper, making them indispensable in the metalworking industry.

Types and Components

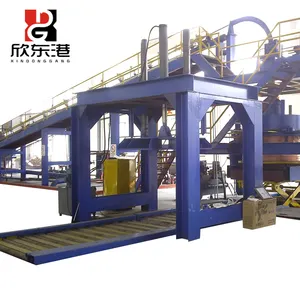

There are several types of wire mills, each serving a specific function in wire production. Rolling mills, for instance, are used for the bulk deformation of metal into wire, while grinding equipment refines the surface of the wire for specific applications. Flour mills, although not directly related to wire production, utilize similar mechanical processes. Key components of a wire mill include motors, gears, and programmable logic controllers (PLCs), which together ensure precise operation and control of the machinery.

Applications and Features

The application of wire mills spans across various industries, from manufacturing plants to building material shops and machinery repair workshops. The produced wire is essential in construction, automotive, electrical, and many other sectors. Features of wire mills often highlight their ease of operation, competitive pricing structures, and automation capabilities, which enhance production efficiency and reliability.

Materials and Advantages

Wire mills are capable of handling a range of materials, each selected for its properties to meet specific industry standards and requirements. The advantages of using advanced wire mills include improved precision in wire diameter, consistency in production, and the ability to handle high-volume demands. These mills are engineered to balance speed with quality, ensuring that the wire produced meets the stringent specifications of various applications.

Choosing the Right Wire Mill

Selecting the appropriate wire mill involves considering factors such as the type of metal to be processed, the desired output, and the specific industry requirements. Prospective buyers should evaluate the condition of the equipment, whether new or used, and its operational capacities, such as speed and automation levels. It is crucial to consider the technical support available, although without implying any guarantees from the platform.

Conclusion

In conclusion, wire mills are a critical component in the production of wire, serving a multitude of industries with their ability to produce high-quality wire in an efficient and reliable manner. While Alibaba.com facilitates the connection between buyers and suppliers of these mills, it is important for buyers to conduct thorough research to select the most suitable machinery for their specific needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4